Page 49 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 49

28 CHP B a s i c s

Boiler/

Steam Combined Combustion Reciprocating Total

Size Range Turbine Cycle Turbine Engine Other Number Total (%)

0–999 kW 7 0 20 662 16 705 71.9

1.0–4.9 MW 15 0 42 83 0 140 14.3

5.0–9.9 MW 4 3 16 16 1 40 4.1

10.0–14.9 MW 3 0 11 7 2 23 2.3

15.0–19.9 MW 7 0 2 0 0 9 0.9

20.0–29.9 MW 5 6 5 2 0 18 1.8

30.0–49.9 MW 8 5 6 0 0 19 1.9

50.0–74.9 MW 11 4 0 0 0 15 1.5

75.0–99.9 MW 0 2 2 0 0 4 0.4

100–199 MW 0 5 0 0 0 5 0.5

200–499 MW 0 2 0 0 0 2 0.2

Total number 60 27 104 770 19 980 100.0

Total (%) 6.1 2.8 10.6 78.6 1.9 100.0

Source: From Onsite (2000).

TABLE 2-7 Number of Existing CHP Installations

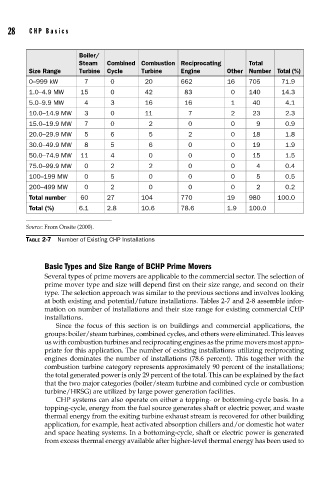

Basic Types and Size Range of BCHP Prime Movers

Several types of prime movers are applicable to the commercial sector. The selection of

prime mover type and size will depend first on their size range, and second on their

type. The selection approach was similar to the previous sections and involves looking

at both existing and potential/future installations. Tables 2-7 and 2-8 assemble infor-

mation on number of installations and their size range for existing commercial CHP

installations.

Since the focus of this section is on buildings and commercial applications, the

groups: boiler/steam turbines, combined cycles, and others were eliminated. This leaves

us with combustion turbines and reciprocating engines as the prime movers most appro-

priate for this application. The number of existing installations utilizing reciprocating

engines dominates the number of installations (78.6 percent). This together with the

combustion turbine category represents approximately 90 percent of the installations;

the total generated power is only 29 percent of the total. This can be explained by the fact

that the two major categories (boiler/steam turbine and combined cycle or combustion

turbine/HRSG) are utilized by large power generation facilities.

CHP systems can also operate on either a topping- or bottoming-cycle basis. In a

topping-cycle, energy from the fuel source generates shaft or electric power, and waste

thermal energy from the exiting turbine exhaust stream is recovered for other building

application, for example, heat activated absorption chillers and/or domestic hot water

and space heating systems. In a bottoming-cycle, shaft or electric power is generated

from excess thermal energy available after higher-level thermal energy has been used to