Page 44 - TPM A Route to World-Class Performance

P. 44

The top-down and bottom-up realities of TPM 25

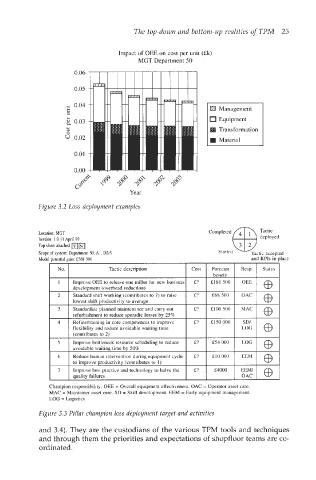

Impact of OEE on cost per unit (Ek)

MGT Department 50

0.06

0.05

.C - 0.04

s

- 0.03 Equipment

u 0.02 I Transformation

Material

0.01

0.00

Year

Figure 3.2 Loss deployment examples

Location: MGT deployed

Top sheet attached mm

Version: 1.0 II April 99

Scope of system: Department 50, AI, D2/3

Model potential gain: f568 500 and KPIs in place

I No. I Tactic description I Cost I Forecast I Resp. I Status I

1 Improve OEE to release one miller for new business f? 2181 500 OEE 03

development (overhead reduction)

2 Standard shift working (contributes to 7) to raise f? E68 500 OAC @

lowest shift productivity to average

3 Standardize planned maintenance and carry out E? f100500 MAC @

refurbishment to reduce sporadic losses by 25%

4 Refinehraining in core competences to improve E? f150000 SDI

flexibility and reduce avoidable waiting time LOG @

(contributes to 2)

5 Improve bottleneck resource scheduling to reduce f? f54 000 LOG @

avoidable waiting time by 50%

6 Reduce human intervention during equipment cycle f? f 10 000 EEM @

to improve productivity (contributes to I)

7 Improve best practice and technology to halve the f? f4000 EEM/ @

quality failures OAC

and 3.4). They are the custodians of the various TPM tools and techniques

and through them the priorities and expectations of shopfloor teams are co-

ordinated.