Page 45 - TPM A Route to World-Class Performance

P. 45

26 TPM-A Route to World-Class Performance

I Pillar champion I

I development I

I plan review I

I I

I

Pilotmhase I: I PilotPhase 11: I PilotPhase 111:

Define current status I Set out I Lead bottom up

and improvement 1 initial priorities I implementation and

goalslpotential I tactics and account- I review process

abilities

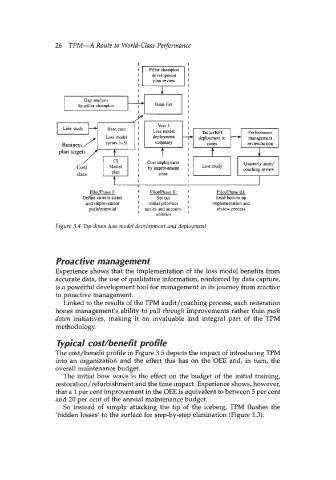

Figure 3.4 Top-down loss model development and deployment

Proactive management

Experience shows that the implementation of the loss model benefits from

accurate data, the use of qualitative information, reinforced by data capture,

is a powerful development tool for management in its journey from reactive

to proactive management.

Linked to the results of the TPM audit/coaching process, each reiteration

hones management’s ability to pull through improvements rather than push

down initiatives, making it an invaluable and integral part of the TPM

methodology.

Typical cosVbenefit profile

The cost/benefit profile in Figure 3.5 depicts the impact of introducing TPM

into an organization and the effect this has on the OEE and, in turn, the

overall maintenance budget.

The initial bow wave is the effect on the budget of the initial training,

restoration/refurbishment and the time impact. Experience shows, however,

that a 1 per cent improvement in the OEE is equivalent to between 5 per cent

and 20 per cent of the annual maintenance budget.

So instead of simply attacking the tip of the iceberg, TPM flushes the

’hidden losses’ to the surface for step-by-step elimination (Figure 1.3).