Page 228 - TPM A Route to World-Class Performance

P. 228

TPM in administration 205

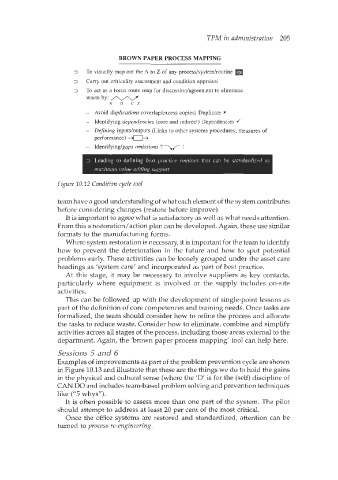

BROWTV PAPER PROCESS MAPPING

2 To visually map out the A to Z of any pmesdsystedroutiine

2 Carry out criticality assessment and condition appraisal

2 To act as a focus route map for discussiodagreement to elminate

waste by:

A B CZ

- Avoid duplications (overlap/excess copies) Duplicate X

- Identlfying dependencies (core and indirect) Dependencies J

- Defining inputs/outputs (Links to other systems procedures, measures of

performance) 0

- Identifyinglgaps omissions ? >,/ !

Figure 10.12 Condition cycle tool

team have a gd understanding of what each element of the system contributes

before considering changes (restore before improve).

It is important to agree what is satisfactory as well as what needs attention.

From this a restoration/action plan can be developed. Again, these use similar

formats to the manufacturing forms.

Where system restoration is necessary, it is important for the team to idenbfy

how to prevent the deterioration in the future and how to spot potential

problems early. These activities can be loosely grouped under the asset care

headings as ‘system care’ and incorporated as part of best practice.

At this stage, it may be necessary to involve suppliers as key contacts,

particularly where equipment is involved or the supply includes on-site

activities.

This can be followed up with the development of single-point lessons as

part of the definition of core competences and training needs. Once tasks are

formalized, the team should consider how to refine the process and allocate

the tasks to reduce waste. Consider how to eliminate, combine and simphfy

activities across all stages of the process, including those areas external to the

department. Again, the ‘brown paper process mapping’ tool can help here.

Sessions 5 and 6

Examples of improvements as part of the problem prevention cycle are shown

in Figure 10.13 and dustrate that these are the things we do to hold the gains

in the physical and dtural sense (where the ’D’ is for the (self) disaphe of

CAN DO and includes team-based problem solving and prevention techniques

like (“5 whys”).

It is often possible to assess more than one part of the system. The pilot

should attempt to address at least 20 per cent of the most critical.

Once the office system are restored and standardized, attention can be

turned to process re-mgineering.