Page 102 - The Geological Interpretation of Well Logs

P. 102

- THE GEOLOGICAL INTERPRETATION OF WELL LOGS -

Table 8.1 The principal uses of the sonic log (conventional, compressiona) wave tools).

Discipline Used for Knowing

Quantitative Petrophysics Porosity Matrix velocity

Fluid velocity

Seismic Interval velocity Integrated travel time

Seismic markers

Seismic calibration Check shots

Acoustic impedance Direct use of sonic log

Qualitative and Geology Lithology Matrix and mineral velocities

semi-quantitative Correlation

Texture

Fracture identification Density log porosities

Compaction and overpressure Normal compaction trends

Geochemistry Source rock evaluation Resistivity log values

compaction and overpressure and to some extent frac- to the typical seismic signal (sonic and seismic velocities

tures. It is frequently used in correlation (Table 8.1). are routinely compared) which has a content in the

10-50 hertz range (i.e. 10-50 cycles per second) and with

wavelengths of 30m-50m (see Section 8.7, Seismic

8.2 Principles of measurement

applications).

The conventional, general purpose sonic tools measure

the time it takes for a sound pulse to travel between a 8.3 Tools

transmitter and a receiver, mounted a set distance away

Modem sonic tools do not consist of just a single emitter

along the logging tool. The pulse measured is that of the

and a single receiver, but of a number of both transmitters

compressional or ‘P’ wave (Figure 8.2) and tool design

and receivers, the actual arrangement depending on the

enables the velocity of this wave in the formation to be

too] type. Modern designs allow unwanted borehole and

measured. The compressional wave is simply the fastest

tool effects to be largely eliminated and give a reliable

or ‘first arrival’, in which particles vibrate in the direction

measure of formation values even in quite poor borehole

of the sense of movement. The compressional wave is fol-

conditions. Typical tool design and use of compensation

lowed by shear and Stoneley waves (Figure 8.2) which, in

can be illustrated by the borehole-compensated (BHC)

the conventional tools, are ignored but in the moder array

sonic tool (Figure 8.4).

acoustic tools, can be fully measured (Section 8.8).

Typical sonic tool transmitters (transducers) are either

magnetostrictive or, more commonly, piezoelectric and

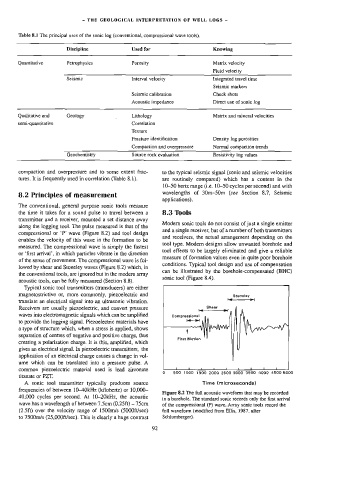

Stanaley

translate an electrical signal into an ultrasonic vibration.

Shear

Receivers are usually piezoelectric, and convert pressure

waves into electromagnetic signals which can be amplified Compressianal

to provide the logging signal. Piezoelectric materials have te

a type of structure which, when a stress is applied, shows bmw

t

separation of centres of negative and positive charge, thus

First Motian

creating a polarisation charge. It is this, amplified, which

gives an electrical signal. In piezoelectric transmitters, the

application of an electrical charge causes a change in vol-

ume which can be translated into a pressure pulse. A

l LL + L i L 1 1 4

common piezoelectric material used is lead zirconate

0 $00 1000 1500 2000 2600 3000 3500 4000 4500 5000

titanate or PZT.

A sonic tool transmitter typically produces source Time {microseconds}

frequencies of between 10-40kHz (kilohertz) or 10,000-

Figure 8.2 The full acoustic waveform that may be recorded

40,000 cycles per second. At 10-20kHz, the acoustic

in a borehole. The standard sonic records only the first arrival

wave has a wavelength of berween 7.5cm (0.25ft} — 75cm of the compressional (P) wave. Array sonic tools record the

(2.5ft) over the velocity range of 1500m/s (S000ft/sec)} full waveform (modified from Ellis, 1987, after

to 7500m/s (25,000ft/sec). This is clearly a huge contrast Schlumberger}.

92