Page 102 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 102

88 I n t e g r a t e d P l a n n i n g S t r a t e g i c P l a n n i n g 89

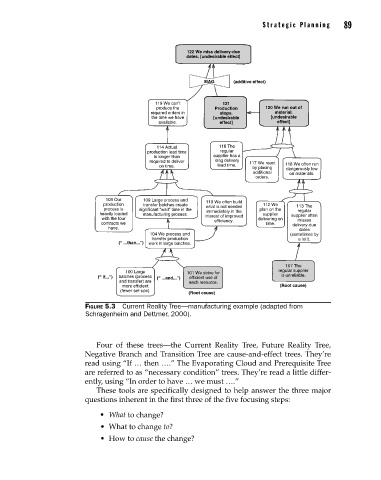

122 We miss delivery-due

dates. [undesirable effect]

MAG (additive effect)

119 We can’t 121

produce the Production 120 We run out of

required orders in stops. material.

the time we have [undesirable [undesirable

available. effect] effect]

114 Actual 116 The

production lead time regular

is longer than supplier has a

required to deliver long delivery 117 We react 118 We often run

on time. lead time. by placing dangerously low

additional on materials.

orders.

108 Our 109 Large process and 110 We often build

production transfer batches create what is not needed 112 We 113 The

process is significant “wait” time in the immediately in the plan on the regular

heavily loaded manufacturing process. interest of improved supplier supplier often

with the four efficiency. delivering on misses

contracts we time. delivery-due

have. dates

104 We process and (sometimes by

transfer production a lot!).

(“ ...than...”) work in large batches.

107 The

100 Large 101 We strive for regular supplier

(“ If...”) batches (process (“ ...and...”) efficient use of is unreliable.

and transfer) are each resource.

more efficient (Root cause)

(fewer set-ups). (Root cause)

Figure 5.3 Current Reality Tree—manufacturing example (adapted from

Schragenheim and Dettmer, 2000).

Four of these trees—the Current Reality Tree, Future Reality Tree,

Negative Branch and Transition Tree are cause-and-effect trees. They’re

read using “If … then ….” The Evaporating Cloud and Prerequisite Tree

are referred to as “nec essary condition” trees. They’re read a little differ-

ently, using “In order to have … we must ….”

These tools are specifically designed to help answer the three major

ques tions inherent in the first three of the five focusing steps:

• What to change?

• What to change to?

• How to cause the change?

05_Pyzdek_Ch05_p061-102.indd 89 11/9/12 5:04 PM