Page 104 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 104

90 I n t e g r a t e d P l a n n i n g S t r a t e g i c P l a n n i n g 91

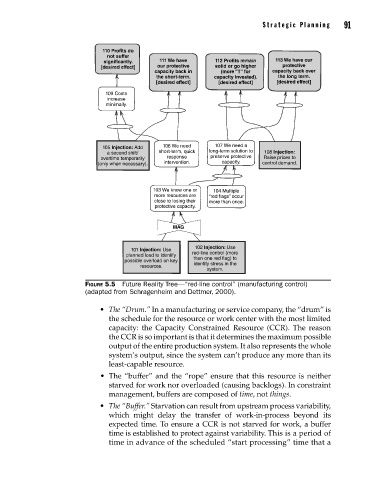

110 Profits do

not suffer

significantly. 111 We have 112 Profits remain 113 We have our

[desired effect] our protective solid or go higher protective

capacity back in (more “T” for capacity back over

the short-term. capacity invested). the long term.

[desired effect] [desired effect] [desired effect]

109 Costs

increase

minimally.

105 Injection: Add 106 We need 107 We need a

a second shift/ short-term, quick long-term solution to 108 Injection:

overtime temporarily response preserve protective Raise prices to

(only when necessary). intervention. capacity. control demand.

103 We know one or 104 Multiple

more resources are “red flags” occur

close to losing their more than once.

protective capacity.

MAG

101 Injection: Use 102 Injection: Use

planned load to identify red-line control (more

possible overload on key than one red flag) to

resources. identify stress in the

system.

Figure 5.5 Future Reality Tree—“red-line control” (manufacturing control)

(adapted from Schragenheim and Dettmer, 2000).

• The “Drum.” In a manufacturing or service company, the “drum” is

the schedule for the resource or work center with the most limited

capacity: the Capacity Constrained Resource (CCR). The reason

the CCR is so important is that it determines the maximum possible

output of the entire production system. It also represents the whole

system’s output, since the system can’t produce any more than its

least-capable resource.

• The “buffer” and the “rope” ensure that this resource is neither

starved for work nor overloaded (causing backlogs). In constraint

management, buffers are composed of time, not things.

• The “Buffer.” Starvation can result from upstream process variability,

which might delay the transfer of work-in-process beyond its

expected time. To ensure a CCR is not starved for work, a buffer

time is established to protect against variability. This is a period of

time in advance of the scheduled “start processing” time that a

05_Pyzdek_Ch05_p061-102.indd 91 11/9/12 5:04 PM