Page 103 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 103

90 I n t e g r a t e d P l a n n i n g S t r a t e g i c P l a n n i n g 91

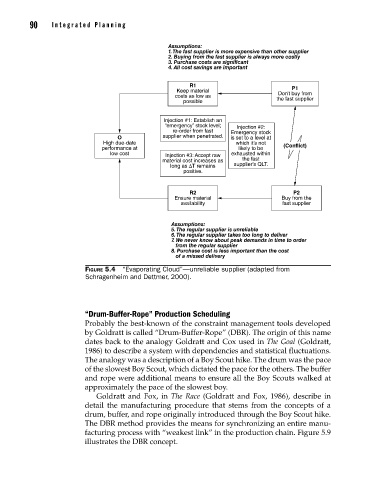

Assumptions:

1. The fast supplier is more expensive than other supplier

2. Buying from the fast supplier is always more costly

3. Purchase costs are significant

4. All cost savings are important

R1

Keep material P1

Don’t buy from

costs as low as the fast supplier

possible

Injection #1: Establish an

“emergency” stock level; Injection #2:

re-order from fast Emergency stock

O supplier when penetrated. is set to a level at

High due-date which it’s not

performance at likely to be (Conflict)

low cost Injection #3: Accept raw exhausted within

material cost increases as the fast

long as ∆T remains supplier’s QLT.

positive.

R2 P2

Ensure material Buy from the

availability fast supplier

Assumptions:

5. The regular supplier is unreliable

6. The regular supplier takes too long to deliver

7. We never know about peak demands in time to order

from the regular supplier

8. Purchase cost is less important than the cost

of a missed delivery

Figure 5.4 “Evaporating Cloud”—unreliable supplier (adapted from

Schragenheim and Dettmer, 2000).

“Drum-Buffer-Rope” Production Scheduling

Probably the best-known of the constraint management tools developed

by Goldratt is called “Drum-Buffer-Rope” (DBR). The origin of this name

dates back to the analogy Goldratt and Cox used in The Goal (Goldratt,

1986) to describe a system with dependencies and statistical fluctuations.

The analogy was a description of a Boy Scout hike. The drum was the pace

of the slowest Boy Scout, which dictated the pace for the others. The buffer

and rope were additional means to ensure all the Boy Scouts walked at

approximately the pace of the slowest boy.

Goldratt and Fox, in The Race (Goldratt and Fox, 1986), describe in

detail the manufacturing procedure that stems from the concepts of a

drum, buffer, and rope originally introduced through the Boy Scout hike.

The DBR method provides the means for synchronizing an entire manu-

facturing process with “weakest link” in the production chain. Figure 5.9

illustrates the DBR con cept.

05_Pyzdek_Ch05_p061-102.indd 90 11/9/12 5:04 PM