Page 269 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 269

256 C o n t i n u o u s I m p r o v e m e n t e f f e c t i v e C h a n g e M a n a g e m e n t 257

prioritizing these opportunities. The PPI is calculated as follows (Juran

and Gryna, 1993):

×

savings probability of success

PPI =

l

c ost × completion time

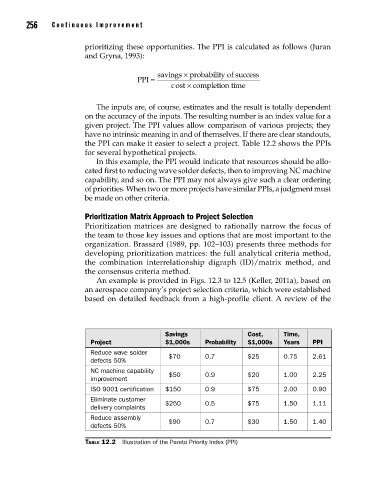

The inputs are, of course, estimates and the result is totally dependent

on the accuracy of the inputs. The resulting number is an index value for a

given project. The PPI values allow comparison of various projects; they

have no intrinsic meaning in and of themselves. If there are clear standouts,

the PPI can make it easier to select a project. Table 12.2 shows the PPIs

for several hypothetical projects.

In this example, the PPI would indicate that resources should be allo-

cated first to reducing wave solder defects, then to improving NC machine

capability, and so on. The PPI may not always give such a clear ordering

of priorities. When two or more projects have similar PPIs, a judgment must

be made on other criteria.

Prioritization Matrix Approach to Project Selection

Prioritization matrices are designed to rationally narrow the focus of

the team to those key issues and options that are most important to the

organization. Brassard (1989, pp. 102–103) presents three methods for

developing prioritization matrices: the full analytical criteria method,

the combination interrelationship digraph (ID)/matrix method, and

the consensus criteria method.

An example is provided in Figs. 12.3 to 12.5 (Keller, 2011a), based on

an aerospace company’s project selection criteria, which were established

based on detailed feedback from a high-profile client. A review of the

Savings Cost, Time,

Project $1,000s Probabi lity $1,000s Years PPI

Reduce wave solder

defects 50% $70 0.7 $25 0.75 2.61

NC machine capability $50 0.9 $20 1.00 2.25

improvement

ISO 9001 certification $150 0.9 $75 2.00 0.90

Eliminate customer $250 0.5 $75 1.50 1.11

delivery complaints

Reduce assembly

defects 50% $90 0.7 $30 1.50 1.40

Table 12.2 Illustration of the Pareto Priority Index (PPI)

12_Pyzdek_Ch12_p241-264.indd 256 11/9/12 5:13 PM