Page 333 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 333

A n a l y z e S t a g e 321

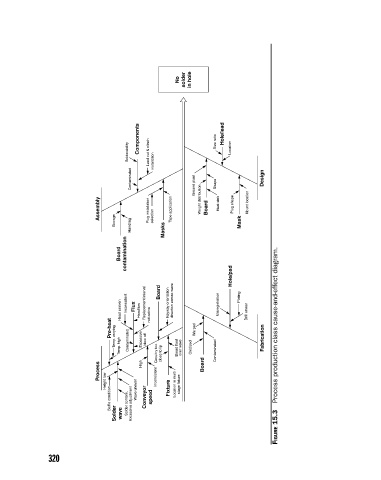

No solder in hole

Components Size ratio Hole/lead

Solderability Lead cut & clinch installation Location

Contaminated Ground plant Shape Design

Assembly Plug installation Tape application Weight distribution Board Heat sink Plug shape Mount location

Storage Handling selection Masks Mask

Board contamination

Hole/pad

Board

Head uneven Inconsistent Flux Head low Replacement interval not active Keyway orientation direction across wave Misregistration Plating Drill smear

Pre-heat Temp. varying Temp. high Contaminated Excessive blow off Board float over wave Oxidized Warped Fabrication Process production class cause-and-effect diagram.

Process Height low High Inconsistent Circuitry too close to lip Location in multi stage fixture Board Contaminated

Baffle condition Solder contam. Excessive adjustment Wave uneven Conveyor speed Fixture

Solder wave

Figure 15.3

320

15_Pyzdek_Ch15_p305-334.indd 320 11/20/12 10:33 PM