Page 447 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 447

434 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 435

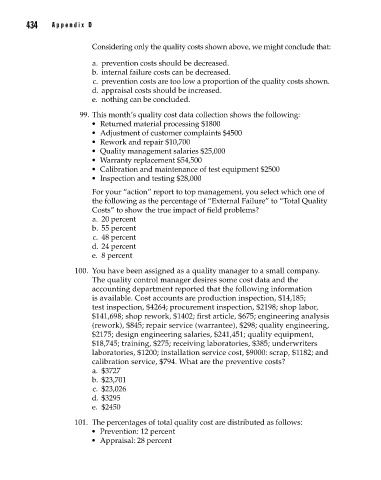

Considering only the quality costs shown above, we might conclude that:

a. prevention costs should be decreased.

b. internal failure costs can be decreased.

c. prevention costs are too low a proportion of the quality costs shown.

d. appraisal costs should be increased.

e. nothing can be concluded.

99. This month’s quality cost data collection shows the following:

• Returned material processing $1800

• Adjustment of customer complaints $4500

• Rework and repair $10,700

• Quality management salaries $25,000

• Warranty replacement $54,500

• Calibration and maintenance of test equipment $2500

• Inspection and testing $28,000

For your “action” report to top management, you select which one of

the following as the percentage of “External Failure” to “Total Quality

Costs” to show the true impact of field problems?

a. 20 percent

b. 55 percent

c. 48 percent

d. 24 percent

e. 8 percent

100. You have been assigned as a quality manager to a small company.

The quality control manager desires some cost data and the

accounting department reported that the following information

is available. Cost accounts are production inspection, $14,185;

test inspection, $4264; procurement inspection, $2198; shop labor,

$141,698; shop rework, $1402; first article, $675; engineering analysis

(rework), $845; repair service (warrantee), $298; quality engineering,

$2175; design engineering salaries, $241,451; quality equipment,

$18,745; training, $275; receiving laboratories, $385; underwriters

laboratories, $1200; installation service cost, $9000: scrap, $1182; and

calibration service, $794. What are the preventive costs?

a. $3727

b. $23,701

c. $23,026

d. $3295

e. $2450

101. The percentages of total quality cost are distributed as follows:

• Prevention: 12 percent

• Appraisal: 28 percent

21_Pyzdek_AppD_Ch21_p413-454.indd 434 11/9/12 5:33 PM