Page 448 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 448

434 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 435

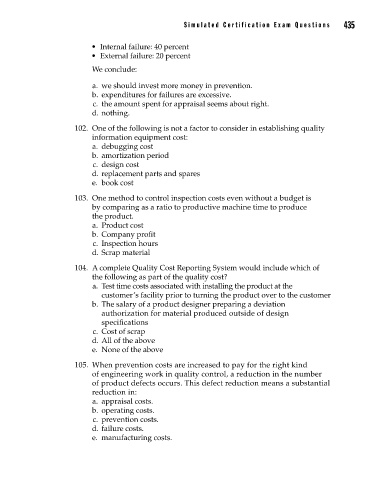

• Internal failure: 40 percent

• External failure: 20 percent

We conclude:

a. we should invest more money in prevention.

b. expenditures for failures are excessive.

c. the amount spent for appraisal seems about right.

d. nothing.

102. One of the following is not a factor to consider in establishing quality

information equipment cost:

a. debugging cost

b. amortization period

c. design cost

d. replacement parts and spares

e. book cost

103. One method to control inspection costs even without a budget is

by comparing as a ratio to productive machine time to produce

the product.

a. Product cost

b. Company profit

c. Inspection hours

d. Scrap material

104. A complete Quality Cost Reporting System would include which of

the following as part of the quality cost?

a. Test time costs associated with installing the product at the

customer’s facility prior to turning the product over to the customer

b. The salary of a product designer preparing a deviation

authorization for material produced outside of design

specifications

c. Cost of scrap

d. All of the above

e. None of the above

105. When prevention costs are increased to pay for the right kind

of engineering work in quality control, a reduction in the number

of product defects occurs. This defect reduction means a substantial

reduction in:

a. appraisal costs.

b. operating costs.

c. prevention costs.

d. failure costs.

e. manufacturing costs.

21_Pyzdek_AppD_Ch21_p413-454.indd 435 11/9/12 5:33 PM