Page 444 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 444

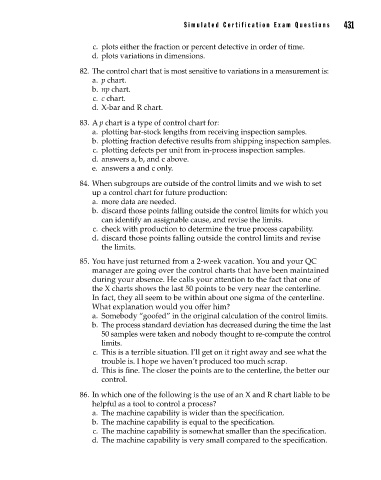

430 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 431

c. plots either the fraction or percent detective in order of time.

d. plots variations in dimensions.

82. The control chart that is most sensitive to variations in a measurement is:

a. p chart.

b. np chart.

c. c chart.

d. X-bar and R chart.

83. A p chart is a type of control chart for:

a. plotting bar-stock lengths from receiving inspection samples.

b. plotting fraction defective results from shipping inspection samples.

c. plotting defects per unit from in-process inspection samples.

d. answers a, b, and c above.

e. answers a and c only.

84. When subgroups are outside of the control limits and we wish to set

up a control chart for future production:

a. more data are needed.

b. discard those points falling outside the control limits for which you

can identify an assignable cause, and revise the limits.

c. check with production to determine the true process capability.

d. discard those points falling outside the control limits and revise

the limits.

85. You have just returned from a 2-week vacation. You and your QC

manager are going over the control charts that have been maintained

during your absence. He calls your attention to the fact that one of

the X charts shows the last 50 points to be very near the centerline.

In fact, they all seem to be within about one sigma of the centerline.

What explanation would you offer him?

a. Somebody “goofed” in the original calculation of the control limits.

b. The process standard deviation has decreased during the time the last

50 samples were taken and nobody thought to re-compute the control

limits.

c. This is a terrible situation. I’ll get on it right away and see what the

trouble is. I hope we haven’t produced too much scrap.

d. This is fine. The closer the points are to the centerline, the better our

control.

86. In which one of the following is the use of an X and R chart liable to be

helpful as a tool to control a process?

a. The machine capability is wider than the specification.

b. The machine capability is equal to the specification.

c. The machine capability is somewhat smaller than the specification.

d. The machine capability is very small compared to the specification.

21_Pyzdek_AppD_Ch21_p413-454.indd 431 11/9/12 5:33 PM