Page 441 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 441

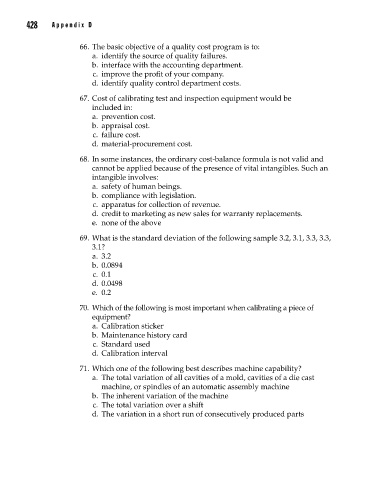

428 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 429

66. The basic objective of a quality cost program is to:

a. identify the source of quality failures.

b. interface with the accounting department.

c. improve the profit of your company.

d. identify quality control department costs.

67. Cost of calibrating test and inspection equipment would be

included in:

a. prevention cost.

b. appraisal cost.

c. failure cost.

d. material-procurement cost.

68. In some instances, the ordinary cost-balance formula is not valid and

cannot be applied because of the presence of vital intangibles. Such an

intangible involves:

a. safety of human beings.

b. compliance with legislation.

c. apparatus for collection of revenue.

d. credit to marketing as new sales for warranty replacements.

e. none of the above

69. What is the standard deviation of the following sample 3.2, 3.1, 3.3, 3.3,

3.1?

a. 3.2

b. 0.0894

c. 0.1

d. 0.0498

e. 0.2

70. Which of the following is most important when calibrating a piece of

equipment?

a. Calibration sticker

b. Maintenance history card

c. Standard used

d. Calibration interval

71. Which one of the following best describes machine capability?

a. The total variation of all cavities of a mold, cavities of a die cast

machine, or spindles of an automatic assembly machine

b. The inherent variation of the machine

c. The total variation over a shift

d. The variation in a short run of consecutively produced parts

21_Pyzdek_AppD_Ch21_p413-454.indd 428 11/9/12 5:33 PM