Page 439 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 439

426 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 427

c. the chief executive of company.

d. production management.

e. an experienced quality manager.

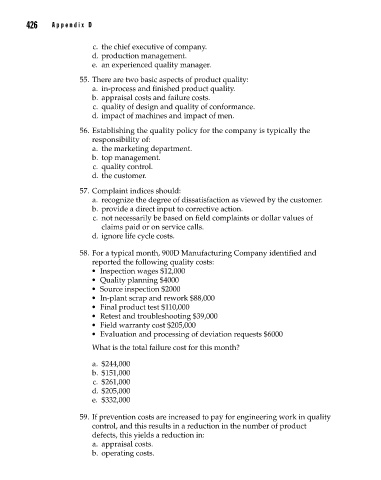

55. There are two basic aspects of product quality:

a. in-process and finished product quality.

b. appraisal costs and failure costs.

c. quality of design and quality of conformance.

d. impact of machines and impact of men.

56. Establishing the quality policy for the company is typically the

responsibility of:

a. the marketing department.

b. top management.

c. quality control.

d. the customer.

57. Complaint indices should:

a. recognize the degree of dissatisfaction as viewed by the customer.

b. provide a direct input to corrective action.

c. not necessarily be based on field complaints or dollar values of

claims paid or on service calls.

d. ignore life cycle costs.

58. For a typical month, 900D Manufacturing Company identified and

reported the following quality costs:

• Inspection wages $12,000

• Quality planning $4000

• Source inspection $2000

• In-plant scrap and rework $88,000

• Final product test $110,000

• Retest and troubleshooting $39,000

• Field warranty cost $205,000

• Evaluation and processing of deviation requests $6000

What is the total failure cost for this month?

a. $244,000

b. $151,000

c. $261,000

d. $205,000

e. $332,000

59. If prevention costs are increased to pay for engineering work in quality

control, and this results in a reduction in the number of product

defects, this yields a reduction in:

a. appraisal costs.

b. operating costs.

21_Pyzdek_AppD_Ch21_p413-454.indd 426 11/9/12 5:33 PM