Page 438 - The Handbook for Quality Management a Complete Guide to Operational Excellence

P. 438

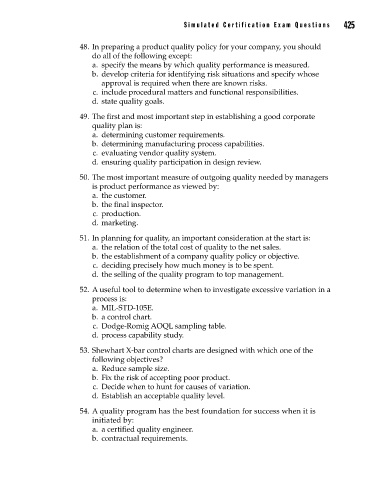

424 A p p e n d i x D S i m u l a t e d C e r t i f i c a t i o n E x a m Q u e s t i o n s 425

48. In preparing a product quality policy for your company, you should

do all of the following except:

a. specify the means by which quality performance is measured.

b. develop criteria for identifying risk situations and specify whose

approval is required when there are known risks.

c. include procedural matters and functional responsibilities.

d. state quality goals.

49. The first and most important step in establishing a good corporate

quality plan is:

a. determining customer requirements.

b. determining manufacturing process capabilities.

c. evaluating vendor quality system.

d. ensuring quality participation in design review.

50. The most important measure of outgoing quality needed by managers

is product performance as viewed by:

a. the customer.

b. the final inspector.

c. production.

d. marketing.

51. In planning for quality, an important consideration at the start is:

a. the relation of the total cost of quality to the net sales.

b. the establishment of a company quality policy or objective.

c. deciding precisely how much money is to be spent.

d. the selling of the quality program to top management.

52. A useful tool to determine when to investigate excessive variation in a

process is:

a. MIL-STD-105E.

b. a control chart.

c. Dodge-Romig AOQL sampling table.

d. process capability study.

53. Shewhart X-bar control charts are designed with which one of the

following objectives?

a. Reduce sample size.

b. Fix the risk of accepting poor product.

c. Decide when to hunt for causes of variation.

d. Establish an acceptable quality level.

54. A quality program has the best foundation for success when it is

initiated by:

a. a certified quality engineer.

b. contractual requirements.

21_Pyzdek_AppD_Ch21_p413-454.indd 425 11/9/12 5:33 PM