Page 150 - The Jet Engine

P. 150

Controls and instrumentation

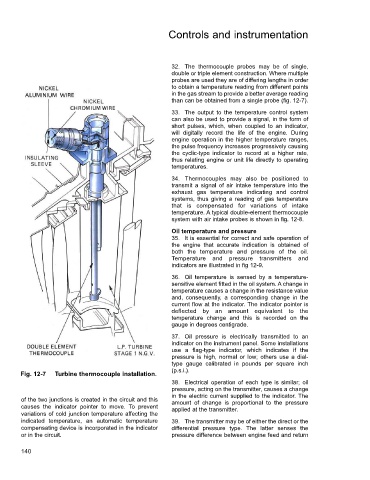

32. The thermocouple probes may be of single,

double or triple element construction. Where multiple

probes are used they are of differing lengths in order

to obtain a temperature reading from different points

in the gas stream to provide a better average reading

than can be obtained from a single probe (fig. 12-7).

33. The output to the temperature control system

can also be used to provide a signal, in the form of

short pulses, which, when coupled to an indicator,

will digitally record the life of the engine. During

engine operation in the higher temperature ranges,

the pulse frequency increases progressively causing

the cyclic-type indicator to record at a higher rate,

thus relating engine or unit life directly to operating

temperatures.

34. Thermocouples may also be positioned to

transmit a signal of air intake temperature into the

exhaust gas temperature indicating and control

systems, thus giving a reading of gas temperature

that is compensated for variations of intake

temperature. A typical double-element thermocouple

system with air intake probes is shown in fig. 12-8.

Oil temperature and pressure

35. It is essential for correct and safe operation of

the engine that accurate indication is obtained of

both the temperature and pressure of the oil.

Temperature and pressure transmitters and

indicators are illustrated in fig 12-9.

36. Oil temperature is sensed by a temperature-

sensitive element fitted in the oil system. A change in

temperature causes a change in the resistance value

and, consequently, a corresponding change in the

current flow at the indicator. The indicator pointer is

deflected by an amount equivalent to the

temperature change and this is recorded on the

gauge in degrees centigrade.

37. Oil pressure is electrically transmitted to an

indicator on the instrument panel. Some installations

use a flag-type indicator, which indicates if the

pressure is high, normal or low; others use a dial-

type gauge calibrated in pounds per square inch

(p.s.i.).

Fig. 12-7 Turbine thermocouple installation.

38. Electrical operation of each type is similar; oil

pressure, acting on the transmitter, causes a change

in the electric current supplied to the indicator. The

of the two junctions is created in the circuit and this amount of change is proportional to the pressure

causes the indicator pointer to move. To prevent applied at the transmitter.

variations of cold junction temperature affecting the

indicated temperature, an automatic temperature 39. The transmitter may be of either the direct or the

compensating device is incorporated in the indicator differential pressure type. The latter senses the

or in the circuit. pressure difference between engine feed and return

140