Page 153 - The Jet Engine

P. 153

Controls and instrumentation

shaft failure occur, are but two examples. On some

engine types, the fuel system is fitted with a control

to enable the engine to be operated by manual

throttling should a main fuel system failure occur.

49. In addition to a fire warning system (Part 14), a

number of other audible or visual warning systems

can be fitted to a gas turbine engine. These may be

for low oil or fuel pressure, excessive vibration or

overheating. Indication of these may be by warning

light, bell or horn. A flashing light is used to attract the

pilot's attention to a central warning panel (C.W.P.)

where the actual fault is indicated.

50. Other instruments and lights warn the pilot of

the selected position of the thrust reverser, the fan

reverser or the afterburner variable nozzle, when

applicable. Gauges also inform the pilot of such

things as hydraulic pressure and flow and generator

output, which are vital to the correct operation of the

aircraft systems.

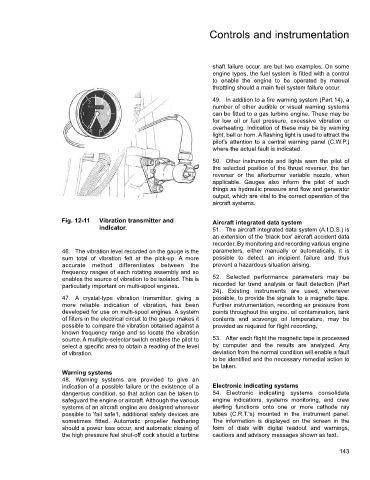

Fig. 12-11 Vibration transmitter and Aircraft integrated data system

indicator. 51. The aircraft integrated data system (A.I.D.S.) is

an extension of the 'black box' aircraft accident data

recorder. By monitoring and recording various engine

46. The vibration level recorded on the gauge is the parameters, either manually or automatically, it is

sum total of vibration felt at the pick-up. A more possible to detect an incipient failure and thus

accurate method differentiates between the prevent a hazardous situation arising.

frequency ranges of each rotating assembly and so

enables the source of vibration to be isolated. This is 52. Selected performance parameters may be

particularly important on multi-spool engines. recorded for trend analysis or fault detection (Part

24). Existing instruments are used, wherever

47. A crystal-type vibration transmitter, giving a possible, to provide the signals to a magnetic tape.

more reliable indication of vibration, has been Further instrumentation, recording air pressure from

developed for use on multi-spool engines. A system points throughout the engine, oil contamination, tank

of filters in the electrical circuit to the gauge makes it contents and scavenge oil temperature, may be

possible to compare the vibration obtained against a provided as required for flight recording,

known frequency range and so locate the vibration

source. A multiple-selector switch enables the pilot to 53. After each flight the magnetic tape is processed

select a specific area to obtain a reading of the level by computer and the results are analyzed. Any

of vibration. deviation from the normal condition will enable a fault

to be identified and the necessary remedial action to

be taken.

Warning systems

48. Warning systems are provided to give an

indication of a possible failure or the existence of a Electronic indicating systems

dangerous condition, so that action can be taken to 54. Electronic indicating systems consolidate

safeguard the engine or aircraft. Although the various engine indications, systems monitoring, and crew

systems of an aircraft engine are designed wherever alerting functions onto one or more cathode ray

possible to 'fail safe1, additional safety devices are tubes (C.R.T.'s) mounted in the instrument panel.

sometimes fitted. Automatic propeller feathering The information is displayed on the screen in the

should a power loss occur, and automatic closing of form of dials with digital readout and warnings,

the high pressure fuel shut-off cock should a turbine cautions and advisory messages shown as text.

143