Page 96 -

P. 96

- i ~'irl rrn~ Pump Selection and Purchasing

PAGE 1 OF

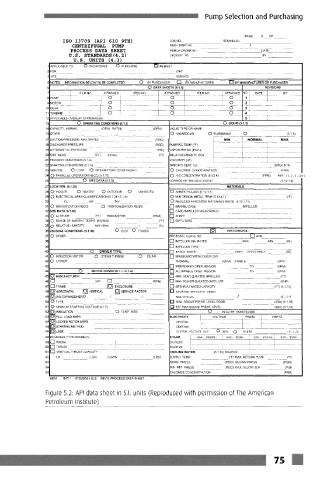

ISO 13709 (API 610 9TH) JOBNO. ITEM NO.(S)

CENTR I FUGAL PUMP REQ ! SPEC NO,

PROCESS DATA SHEET PURCHORDER NO. DATE

BY

U.S. STANDARDS (4.2) ~,zRY No

U.S. UNITS (4.3)

IIAPPLK::ABLE TO: O PROPOSALS O PURCHASE [] AS BUILT

|

21FO L . . . . . . . . UNiT

SERVICE

31S'TL . . . . . .

•

5|NOTES: INFORMATION BELOW TO BE COMPLETED: O BY PURCHASER. [] BY MANUFACTURER r BY MANUFACTURER OR PURCHASER

61 0 DATA SHEETS (&1.1) REVISIONS

ITEM NO, ATTACHED ATTACHED ATTACHED NO, DATE BY

PUMP O O O 1

MOTOR ' ~ 0 O O 2

O O 3

TURBINE I O O O 4

APPL!CABLE OVERLAY STANDARD(S): 5

O OPERATING CONDITIONS (5.1,3) O LIQUID (5.1.3)

CAPACITY. NORMAL (GPM) P~,TED (GPM) LIQUID TYPE OR NAME

OTHER O H/WARDOUS O FLAMMABLE O (5.1.5)

SUCTION PRESSURE MAX,/FCA'FED i (PSIG) MAX.

DISCHARGE PRESSURE (PSIG)

D~FFERENTIAL PRESSURE (PSD VAPOR PRESS. (PSLA)

IDIFF. HEAD (FT) NPSHA (FT) RELATIVE DENSITY (SG):

PROCESS VARIATIONS (5.1.4) VISCOSITY (cP)

STARTING CONDITIONS (5.1,4) SPECIFIC HEAT, Cp (B'TU/LB ~

SERVICE: O CONT, O INTERMI'FF. ENT(STARTSiDAY) O CHLORIDE CONCENTRATION (PPM)

O PARALLEL OPERATION REQ'D (5.1.13) O H2S CONCENTRATION (6.5.2,4) (PPM) WET (5.2.1.12c)

O SITE DATA (5.1.3) CORROSIVE / EROSIVE AGENT (5.12,1.9)

LOCATION: (5,1,30)

O INDOOR O HEATED O OUTDOOR O UNHEATED O ANNEX H CLASS (5,12.1.1)

O ELECTRICAL AREA CLASSIFICATION (5,1,24 / 6.1.4) O MIN DESIGN METAL TEMP (5.12.4.I)

CL GR DIV O REDUCED HARDNESS MATERIALS REQ'D (5.12,1,11)

0 WINTERIZATION REQ'D 0 TROP~CALIZATION REQ'D, [] BARREL/CASE ~MPELLER

SITE DATA (5,1,30) [] CASE/iMPELLER WEAR RINGS

O ALTITUDE (FT} BAROMETER (PStA} [] SHAFT

O RANGE OF AMBIENT TEMPS: MtN'MAX. / (~ [] DIFFUSERS

O RELATIVE HUMIDITY: Mff~ i MAX _ _ / _ _ (%)

UNUSUAL CONDITIONS: (5,1,30) O DUST O FUMES PERFORMANCE :

O OTHER PROPOSAL CURVE NO. [] RPM

[] IMPELLER DtA. RATED MAX. MIN, (IN,)

[] IMPELLER TYPE

O DRIVER TYPE [] RATED POWER {BHP) EFFICIENCY (~

O iNDUCTION MOTOR O STEAM TURBINE O GEAR [] M~NIMUM CONTINUOUS FLOW:

O OTHER THERMAL (GPM) STABLE (GPM)

[] PREFERRED OPER. REGION TO (GPM)

O t~OTOR DRIVER ((kt,1 i 6.1,4) [] ALLOWABLE OPER. REGION T O ~ (GPM}

MANUFACTURER [] MAX, HEAD @ FLATED IMPELLER (FT)

[] (HP) [] (RPM) [] MAX POWER @ RATED IMPELLER (BHP)

[] FRAME F O'] ENCLOSURE [] NPSHRAT [RATED C&PAC~TY (FT) (5.1.10)

r O-] HORIZONTAL [~ VERTICAL FO-] SERVICE FACTOR [] SUCTION SPECIFIC SPEED

FO-] VOLTS/PHASE/H ERTZ / / tc~.x / AC:I":J AL / (5, I. 11 )

O TYPE [] MAX, SOUND PRESS. LEVEL REQ'D (dBA) (5.1,16)

O MINIMUM STARTING VOLTAGE (6,l,5) O 'TEMP, RISE [] EST MAX SOUND PRESS, LEVEL u~z~zT-z "co~T~o~s (dBA) (5.1.16)

0

INSULATION

~ FULL LOAD AMPS ELECTRICITY VOLTAGE PHASE t HERTZ

LOCKED ROTOR AMPS

~-] STARTING METHOD D?.IVERS [ L

HEATING

Fo--] LUBE SYST.~;M VOLTAGE DIP O 80% O OTHER {6.].5}

BEARINGS (TYPE/NUMBER): STEAM I M-A x, PRESS~ MAX. TEMP. MIN. PRESS MIN~ TEMP.

[] RADIAL / iDRZVERS

[] THRUST HEATING

[] VERTICAL THRUST CAPACITY COOLING WATER: (5.1,19) SOURCE

UP (LBS) DOWN (LBS) SUPPLY TEMP. (~ MAX. RETURN TEMP, (~

NORM. PRESS, (PSiG) DESIGN PRESS. (PSIG)

MIN. RET, PRESS. (PSIG) MAX. ALLOW, D.P, (PSi)

CHLORIDE CONCENTRATION: (PPM)

Figure 5.2: API data sheet in S.I. units (Reproduced with permission of The American

Petroleum Institute)

m

_ m

i