Page 99 -

P. 99

The Practical Pumping Handbook ~::::: .......... ::::::::::::::::::::::::::::::::::::::::::::::: ............... :::::::::::::::::::::::: IIIBB!EE

flow rate than was originally

planned. From this point the H

Variable System will slowly move A

vertically upwards to the Ultimate

System. This will bring the

operating point back along the

pump curve to the Design Flow

and a smooth operating condition. Lowest 1

As a result of this decision, the

pump will therefore be operating

for most of the time under adverse Design Q

conditions which will inevitably Flow /

result in poor reliability and Figure 5.6: System curve with pump A

premature failure. In addition, the

batch will be transferred at a much

higher speed than was anticipated as the pump will always be operating

at a flow rate higher than was selected.

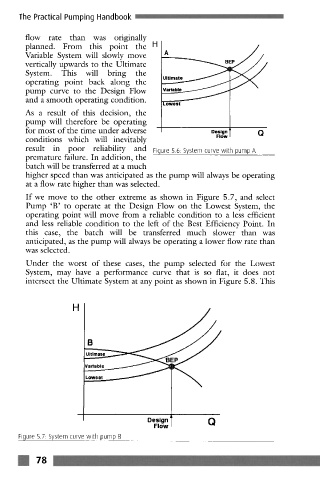

If we move to the other extreme as shown in Figure 5.7, and select

Pump 'B' to operate at the Design Flow on the Lowest System, the

operating point will move from a reliable condition to a less efficient

and less reliable condition to the left of the Best Efficiency Point. In

this case, the batch will be transferred much slower than was

anticipated, as the pump will always be operating a lower flow rate than

was selected.

Under the worst of these cases, the pump selected for the Lowest

System, may have a performance curve that is so flat, it does not

intersect the Ultimate System at any point as shown in Figure 5.8. This

H

B

Design Q

Flow

Figure 5.7. System curve with pump B

m 78