Page 116 - The Tribology Handbook

P. 116

Selection of rolling bearings A20

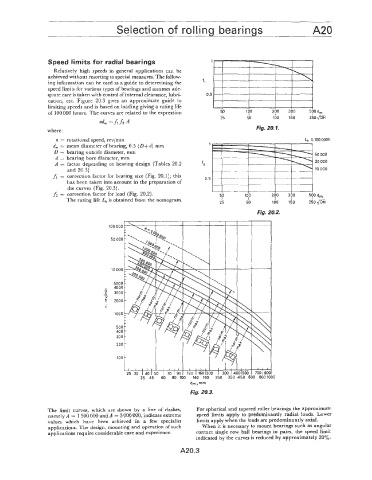

Speed limits for radial bearings 1

Relatively high speeds in general applications can be

achieved without resorting to special measures. The follow-

ing information can be used as a guide to determining the f,

speed limits for various types of bearings and assumes ade-

quate care is taken with control ofinternal clearance, lubri- 0.5

cation, etc. Figure 20.3 gives an approximate guide to

limiting speeds and is based on loading giving a rating life

of 100 000 hours. The curves are related to the expression

where : Fig. 20.7.

n = rotational speed, revlrnin L. L 100 OOOh

d, = mean diameter of bearing, 0.5 (D+d) mm 1

D = bearing outside diameter, mm

d = bearing bore diameter, mm 50 000

A = factor depending on bearing design (Tables 20.2 t 20 000

and 20.3) 10 000

'

1

fl = correction factor for bearing size (Fig. 20.1); this 0.5 1

has belen taken into account in the preparation of I

the cui-ves (Fig. 20.3). I I I I 1

I

I

t

I

f2 = correction factor for load (Fig. 20.2). I SO 100 200 300 5bOd,

I

I

I

I

The rating life Lh is obtained from the nomogram.

25 50 100 150 240m

Rg. 20.2.

Rg. 20.3.

The limit CUI ves, which are shown by a line of dashes, For spherical and tapered roller bearings the approximate

namely A = 1 500 000 and A = 3 000 000, indicate extreme speed limits apply to predominantly radial loads. Lower

values which have been achieved in a few specialist limits apply when the loads are predominantly axial.

applications. The design, mounting and operation of such When it is necessary to mount bearings such as angular

applications require considerable care and experience. contact single row ball bearings in pairs, the speed limit

indicated by the curves is reduced by approximately 20%.

A20.3