Page 590 - The Mechatronics Handbook

P. 590

0066_Frame_C20 Page 60 Wednesday, January 9, 2002 5:49 PM

Piezomotors are easily miniaturized; thus, micromotors are successfully developed. The rotational

motor [5] of this type is a good example. It is 2 mm in diameter, 0.3 mm in height, and its volume is

3

0.49 mm . The motor stably rotates at any posture and the starting torque is about 3.2 µNm.

Piezoactuators with Several Degrees of Freedom

Piezoelectric actuators with several degrees of freedom allow new class of mechanisms, capable of

changing their parameters or kinematic structure under control. If one or both links of the kinematic

pair are made from piezoactive material, it is possible to generate static displacement of its elements and

quasi-static or resonant oscillations, resulting in generating forces or torque in contact area of links.

Motion of one link relative to the other is obtained. Such kinematic pairs can be defined as active. Active

kinematic pairs are characterized by

• Control of number of degrees of freedom. The simplest one is to control friction in the pair,

usually when the elements of the pair are closed by force. Here either the friction coefficient or

magnitude of the force executing the closure can be varied. This is achieved by excitation of high

frequency tangential or normal vibrations in the contact area of the pair.

• Generation of forces or torque in the contact area between links. The direction of generated forces

or torque is controlled by special shift of oscillations, e.g., by activating specific by sectioned

electrodes of the transducer.

• Possibilities to realize additional features: self-diagnostics, multifunctionality, self-repair, self-

adaptation.

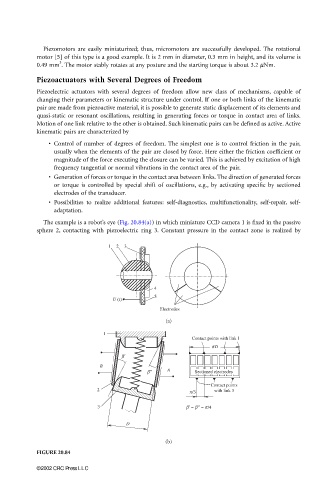

The example is a robot’s eye (Fig. 20.84(a)) in which miniature CCD camera 1 is fixed in the passive

sphere 2, contacting with piezoelectric ring 3. Constant pressure in the contact zone is realized by

1 2 3

4

5

U (t)

Electrodes

(a)

1

Contact points with link 1

pD

b ′

B

b ′′ A Sectioned electrodes

Contact points

2 with link 3

p/3

3 b ′ = b ′′ = p/4

D

(b)

FIGURE 20.84

©2002 CRC Press LLC