Page 227 - Trenchless Technology Piping Installation and Inspection

P. 227

Pr oject Considerations for Horizontal Dir ectional Drilling 191

Line

pipe

string

Pull head

Swivel

Swab

Drill stem

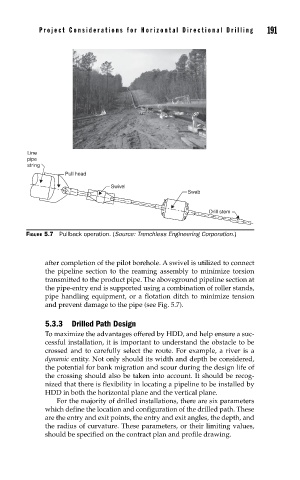

FIGURE 5.7 Pullback operation. (Source: Trenchless Engineering Corporation.)

after completion of the pilot borehole. A swivel is utilized to connect

the pipeline section to the reaming assembly to minimize torsion

transmitted to the product pipe. The aboveground pipeline section at

the pipe-entry end is supported using a combination of roller stands,

pipe handling equipment, or a flotation ditch to minimize tension

and prevent damage to the pipe (see Fig. 5.7).

5.3.3 Drilled Path Design

To maximize the advantages offered by HDD, and help ensure a suc-

cessful installation, it is important to understand the obstacle to be

crossed and to carefully select the route. For example, a river is a

dynamic entity. Not only should its width and depth be considered,

the potential for bank migration and scour during the design life of

the crossing should also be taken into account. It should be recog-

nized that there is flexibility in locating a pipeline to be installed by

HDD in both the horizontal plane and the vertical plane.

For the majority of drilled installations, there are six parameters

which define the location and configuration of the drilled path. These

are the entry and exit points, the entry and exit angles, the depth, and

the radius of curvature. These parameters, or their limiting values,

should be specified on the contract plan and profile drawing.