Page 39 - Using ANSYS for Finite Element Analysis Dynamic, Probabilistic, Design and Heat Transfer Analysis

P. 39

26 • using ansys for finite eLement anaLysis

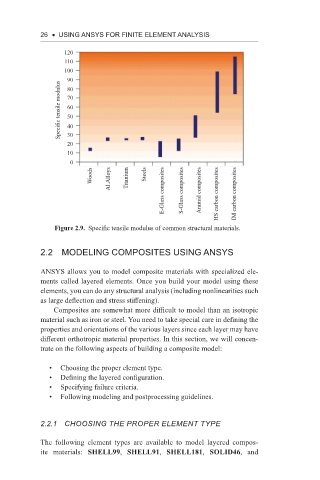

120

110

100

90

Specific tensile modulus 70

80

60

50

40

30

20

10

0

E-Glass composites S-Glass composites Aramid composites HS carbon composites IM carbon composites

Woods Al.Alloys Titanium Steels

Figure 2.9. Specific tensile modulus of common structural materials.

2.2 modeLing ComPosites using ansys

ANSYS allows you to model composite materials with specialized ele-

ments called layered elements. Once you build your model using these

elements, you can do any structural analysis (including nonlinearities such

as large deflection and stress stiffening).

Composites are somewhat more difficult to model than an isotropic

material such as iron or steel. You need to take special care in defining the

properties and orientations of the various layers since each layer may have

different orthotropic material properties. In this section, we will concen-

trate on the following aspects of building a composite model:

• Choosing the proper element type.

• Defining the layered configuration.

• Specifying failure criteria.

• Following modeling and postprocessing guidelines.

2.2.1 ChooSing The PRoPeR eLeMenT TyPe

The following element types are available to model layered compos-

ite materials: SHELL99, SHELL91, SHELL181, SOLID46, and