Page 42 - Using ANSYS for Finite Element Analysis Dynamic, Probabilistic, Design and Heat Transfer Analysis

P. 42

composite materials • 29

• SOLID65, the 3-D reinforced concrete solid element, models

an isotropic medium with optional reinforcing in three different

user-defined orientations.

• BEAM188 and BEAM189, the 3-D finite strain beam elements,

can have their sections built up with multiple materials.

2.2.2 DeFining The LAyeReD ConFigURATion

The most important characteristic of a composite material is its layered

configuration. Each layer may be made of a different orthotropic material

and may have its principal directions oriented differently. For laminated

composites, the fiber directions determine layer orientation. Two methods

are available to define the layered configuration:

• By specifying individual layer properties.

• By defining constitutive matrices that relate generalized forces and

moments to generalized strains and curvatures (available only for

SOLID46 and SHELL99).

2.2.2.1 Specifying individual Layer Properties

With this method, the layer configuration is defined layer-by-layer from

bottom to top. The bottom layer is designated as layer 1, and additional

layers are stacked from bottom to top in the positive Z (normal) direction

of the element coordinate system. You need to define only half of the lay-

ers if stacking symmetry exists.

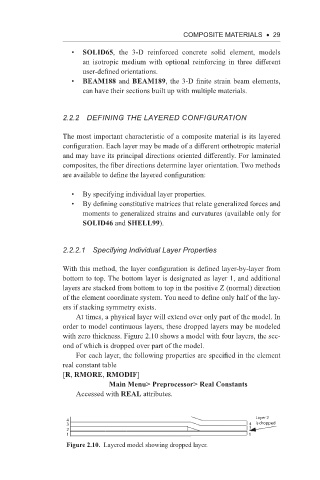

At times, a physical layer will extend over only part of the model. In

order to model continuous layers, these dropped layers may be modeled

with zero thickness. Figure 2.10 shows a model with four layers, the sec-

ond of which is dropped over part of the model.

For each layer, the following properties are specified in the element

real constant table

[R, RMORE, RMODIF]

Main Menu> Preprocessor> Real Constants

Accessed with REAL attributes.

Layer 2

4

3 4 is dropped

2 3

1 1

Figure 2.10. Layered model showing dropped layer.