Page 46 - Using ANSYS for Finite Element Analysis Dynamic, Probabilistic, Design and Heat Transfer Analysis

P. 46

composite materials • 33

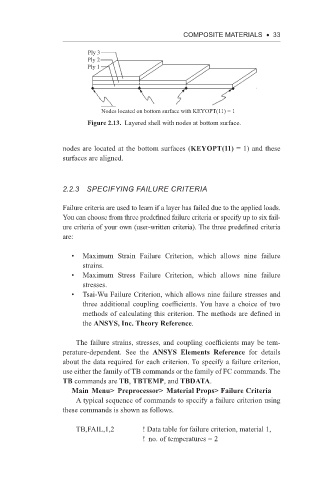

Ply 3

Ply 2

Ply 1

Nodes located on bottom surface with KEYOPT(11) = 1

Figure 2.13. Layered shell with nodes at bottom surface.

nodes are located at the bottom surfaces (KEYOPT(11) = 1) and these

surfaces are aligned.

2.2.3 SPeCiFying FAiLURe CRiTeRiA

Failure criteria are used to learn if a layer has failed due to the applied loads.

You can choose from three predefined failure criteria or specify up to six fail-

ure criteria of your own (user-written criteria). The three predefined criteria

are:

• Maximum Strain Failure Criterion, which allows nine failure

strains.

• Maximum Stress Failure Criterion, which allows nine failure

stresses.

• Tsai-Wu Failure Criterion, which allows nine failure stresses and

three additional coupling coefficients. You have a choice of two

methods of calculating this criterion. The methods are defined in

the ANSYS, Inc. Theory Reference.

The failure strains, stresses, and coupling coefficients may be tem-

perature-dependent. See the ANSYS Elements Reference for details

about the data required for each criterion. To specify a failure criterion,

use either the family of TB commands or the family of FC commands. The

TB commands are TB, TBTEMP, and TBDATA.

Main Menu> Preprocessor> Material Props> Failure Criteria

A typical sequence of commands to specify a failure criterion using

these commands is shown as follows.

TB,FAIL,1,2 ! Data table for failure criterion, material 1,

! no. of temperatures = 2