Page 45 - Using ANSYS for Finite Element Analysis Dynamic, Probabilistic, Design and Heat Transfer Analysis

P. 45

32 • using ansys for finite eLement anaLysis

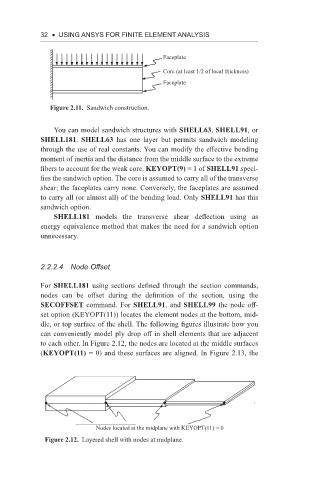

Faceplate

Core (at least 1/2 of local thickness)

Faceplate

Figure 2.11. Sandwich construction.

You can model sandwich structures with SHELL63, SHELL91, or

SHELL181. SHELL63 has one layer but permits sandwich modeling

through the use of real constants. You can modify the effective bending

moment of inertia and the distance from the middle surface to the extreme

fibers to account for the weak core. KEYOPT(9) = 1 of SHELL91 speci-

fies the sandwich option. The core is assumed to carry all of the transverse

shear; the faceplates carry none. Conversely, the faceplates are assumed

to carry all (or almost all) of the bending load. Only SHELL91 has this

sandwich option.

SHELL181 models the transverse shear deflection using as

energy equivalence method that makes the need for a sandwich option

unnecessary.

2.2.2.4 node offset

For SHELL181 using sections defined through the section commands,

nodes can be offset during the definition of the section, using the

SECOFFSET command. For SHELL91, and SHELL99 the node off-

set option (KEYOPT(11)) locates the element nodes at the bottom, mid-

dle, or top surface of the shell. The following figures illustrate how you

can conveniently model ply drop off in shell elements that are adjacent

to each other. In Figure 2.12, the nodes are located at the middle surfaces

(KEYOPT(11) = 0) and these surfaces are aligned. In Figure 2.13, the

Nodes located at the midplane with KEYOPT(11) = 0

Figure 2.12. Layered shell with nodes at midplane.