Page 193 - Valve Selection Handbook

P. 193

180 Valve Selection Handbook

Effect of incompressible fluids on valve behavior. Because liquids are

nearly incompressible and their density is high compared with gases,

small changes in inlet flow velocity produce high pressure changes. Dur-

ing the opening and closing stages of the valve, the pressure changes

translate immediately into changes of valve lift. The lift changes, in turn,

influence the pressure changes. Liquid relief valves are therefore more

readily prone to valve chatter than valves for gas service. However, fitting

liquid relief valves with friction dampers as shown in the valve in Figure

5-14 and discussed in a subsequent chapter under the subject of "Oscilla-

tion Dampers" can avoid valve chatter altogether.

Vacuum Relief Valves

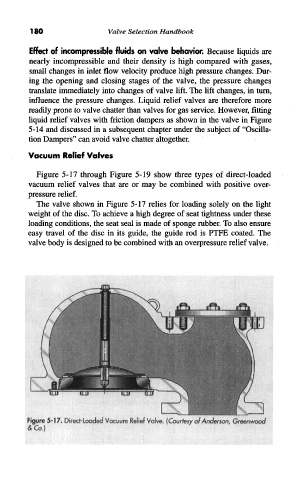

Figure 5-17 through Figure 5-19 show three types of direct-loaded

vacuum relief valves that are or may be combined with positive over-

pressure relief.

The valve shown in Figure 5-17 relies for loading solely on the light

weight of the disc. To achieve a high degree of seat tightness under these

loading conditions, the seat seal is made of sponge rubber. To also ensure

easy travel of the disc in its guide, the guide rod is PTFE coated. The

valve body is designed to be combined with an overpressure relief valve.

Figure 5-17, Direct-loaded Vaeuym Relief Valve, (Coyrfesv ol Anderson, Greenwood

&Co.)