Page 202 - Valve Selection Handbook

P. 202

Pressure Relief Valves 189

tion elements made of hard electro graphite that are packed in a chamber

between spring-loaded compression elements to force the friction ele-

ments against the stem. By this construction, the required amount of fric-

tion for a specific application can be controlled.

Hard electro graphite has little dynamic friction scatter and the differ-

ence between static and dynamic friction is small. The friction force over

the lift is therefore relatively uniform. Because static friction is low, its

effect on the set pressure can be taken into account when setting the

valve. Once the static friction has been overcome, there is no further

impediment to the valve opening speed.

It is interesting to note that with very small amplitudes of oscillation,

or at low frequencies, even a small amount of dry friction corresponds to

a very large amount of equivalent viscous damping. This means that in

the absence of significant disturbances, dry friction can be effective at

preventing chatter. However, if the flow or pressure disturbances exceed

the design limits of the dry friction device, the damper may not be able to

damp out the oscillations.

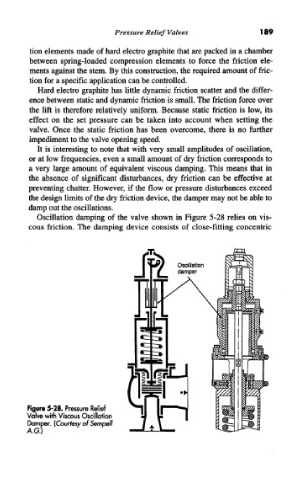

Oscillation damping of the valve shown in Figure 5-28 relies on vis-

cous friction. The damping device consists of close-fitting concentric

Figure 5-28. Pressure Relief

Valve with Viscous Oscillation

Damper. (Courtesy of Sempell

A.G.)