Page 236 - Materials Chemistry, Second Edition

P. 236

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 207

Municipal Solid Waste Processing; Materials Recovery Facilities 207

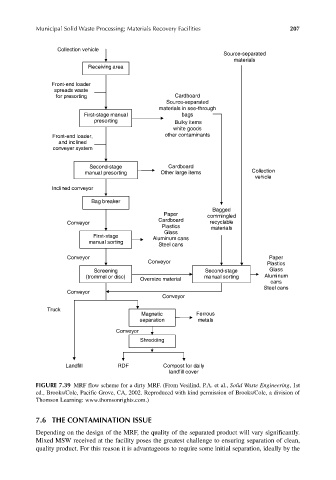

Collection vehicle

Source-separated

materials

Receiving area

Front-end loader

spreads waste

for presorting Cardboard

Source-separated

materials in see-through

First-stage manual bags

presorting Bulky items

white goods

Front-end loader, other contaminants

and inclined

conveyer system

Second-stage Cardboard

manual presorting Other large items Collection

vehicle

Inclined conveyor

Bag breaker

Bagged

Paper commingled

Cardboard

Conveyor recyclable

Plastics materials

Glass

First-stage Aluminum cans

manual sorting

Steel cans

Conveyor Paper

Conveyor Plastics

Screening Second-stage Glass

(trommel or disc) Oversize material manual sorting Aluminum

cans

Steel cans

Conveyor

Conveyor

Truck

Magnetic Ferrous

separation metals

Conveyor

Shredding

Landfill RDF Compost for daily

landfill cover

FIGURE 7.39 MRF flow scheme for a dirty MRF. (From Vesilind, P.A. et al., Solid Waste Engineering, 1st

ed., Brooks/Cole, Pacific Grove, CA, 2002. Reproduced with kind permission of Brooks/Cole, a division of

Thomson Learning: www.thomsonrights.com.)

7.6 THE CONTAMINATION ISSUE

Depending on the design of the MRF, the quality of the separated product will vary significantly.

Mixed MSW received at the facility poses the greatest challenge to ensuring separation of clean,

quality product. For this reason it is advantageous to require some initial separation, ideally by the