Page 237 - Materials Chemistry, Second Edition

P. 237

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 208

208 Waste Management Practices: Municipal, Hazardous, and Industrial

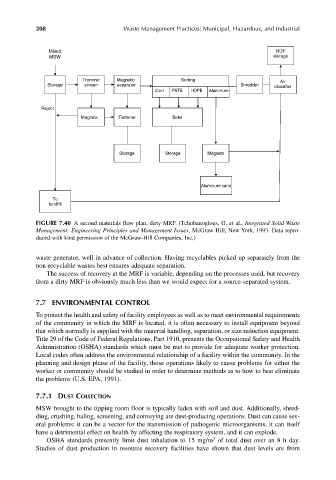

Mixed RDF

MSW storage

Trommel Magnetic Sorting Air

Storage screen separator Shredder

classifier

Corr PETE HDPE Aluminum

Reject

Magnets Flattener Baler

Storage Storage Magnets

Aluminum cans

To

landfill

FIGURE 7.40 A second materials flow plan, dirty MRF. (Tchobanoglous, G. et al., Integrated Solid Waste

Management: Engineering Principles and Management Issues, McGraw Hill, New York, 1993. Data repro-

duced with kind permission of the McGraw-Hill Companies, Inc.)

waste generator, well in advance of collection. Having recyclables picked up separately from the

non-recyclable wastes best ensures adequate separation.

The success of recovery at the MRF is variable, depending on the processes used, but recovery

from a dirty MRF is obviously much less than we would expect for a source-separated system.

7.7 ENVIRONMENTAL CONTROL

To protect the health and safety of facility employees as well as to meet environmental requirements

of the community in which the MRF is located, it is often necessary to install equipment beyond

that which normally is supplied with the material handling, separation, or size reduction equipment.

Title 29 of the Code of Federal Regulations, Part 1910, presents the Occupational Safety and Health

Administration (OSHA) standards which must be met to provide for adequate worker protection.

Local codes often address the environmental relationship of a facility within the community. In the

planning and design phase of the facility, those operations likely to cause problems for either the

worker or community should be studied in order to determine methods as to how to best eliminate

the problems (U.S. EPA, 1991).

7.7.1 DUST COLLECTION

MSW brought to the tipping room floor is typically laden with soil and dust. Additionally, shred-

ding, crushing, baling, screening, and conveying are dust-producing operations. Dust can cause sev-

eral problems: it can be a vector for the transmission of pathogenic microorganisms, it can itself

have a detrimental effect on health by affecting the respiratory system, and it can explode.

3

OSHA standards presently limit dust inhalation to 15 mg/m of total dust over an 8 h day.

Studies of dust production in resource recovery facilities have shown that dust levels are from