Page 625 - Materials Chemistry, Second Edition

P. 625

CAT3525_C20.qxd 1/27/2005 12:54 PM Page 596

596 Waste Management Practices: Municipal, Hazardous, and Industrial

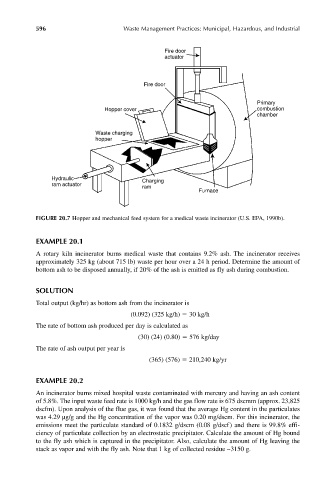

Fire door

actuator

Fire door

Primary

Hopper cover combustion

chamber

Waste charging

hopper

Hydraulic Charging

ram actuator

ram

Furnace

FIGURE 20.7 Hopper and mechanical feed system for a medical waste incinerator (U.S. EPA, 1990b).

EXAMPLE 20.1

A rotary kiln incinerator burns medical waste that contains 9.2% ash. The incinerator receives

approximately 325 kg (about 715 lb) waste per hour over a 24 h period. Determine the amount of

bottom ash to be disposed annually, if 20% of the ash is emitted as fly ash during combustion.

SOLUTION

Total output (kg/hr) as bottom ash from the incinerator is

(0.092) (325 kg/h) 30 kg/h

The rate of bottom ash produced per day is calculated as

(30) (24) (0.80) 576 kg/day

The rate of ash output per year is

(365) (576) 210,240 kg/yr

EXAMPLE 20.2

An incinerator burns mixed hospital waste contaminated with mercury and having an ash content

of 5.8%. The input waste feed rate is 1000 kg/h and the gas flow rate is 675 dscmm (approx. 23,825

dscfm). Upon analysis of the flue gas, it was found that the average Hg content in the particulates

was 4.29 µg/g and the Hg concentration of the vapor was 0.20 mg/dscm. For this incinerator, the

emissions meet the particulate standard of 0.1832 g/dscm (0.08 g/dscf) and there is 99.8% effi-

ciency of particulate collection by an electrostatic precipitator. Calculate the amount of Hg bound

to the fly ash which is captured in the precipitator. Also, calculate the amount of Hg leaving the

stack as vapor and with the fly ash. Note that 1 kg of collected residue ~3150 g.