Page 624 - Materials Chemistry, Second Edition

P. 624

CAT3525_C20.qxd 1/27/2005 12:54 PM Page 595

Medical and Infectious Wastes 595

Flue

Secondary chamber

Secondary burner

Secondary combustion

air blower

Mechanical charge

system

Viewport

Ash removal

door

Primary

burner

Primary chamber

Primary combustion

air blower

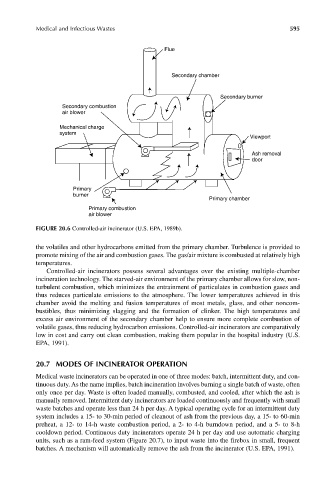

FIGURE 20.6 Controlled-air incinerator (U.S. EPA, 1989b).

the volatiles and other hydrocarbons emitted from the primary chamber. Turbulence is provided to

promote mixing of the air and combustion gases. The gas/air mixture is combusted at relatively high

temperatures.

Controlled-air incinerators possess several advantages over the existing multiple-chamber

incineration technology. The starved-air environment of the primary chamber allows for slow, non-

turbulent combustion, which minimizes the entrainment of particulates in combustion gases and

thus reduces particulate emissions to the atmosphere. The lower temperatures achieved in this

chamber avoid the melting and fusion temperatures of most metals, glass, and other noncom-

bustibles, thus minimizing slagging and the formation of clinker. The high temperatures and

excess air environment of the secondary chamber help to ensure more complete combustion of

volatile gases, thus reducing hydrocarbon emissions. Controlled-air incinerators are comparatively

low in cost and carry out clean combustion, making them popular in the hospital industry (U.S.

EPA, 1991).

20.7 MODES OF INCINERATOR OPERATION

Medical waste incinerators can be operated in one of three modes: batch, intermittent duty, and con-

tinuous duty. As the name implies, batch incineration involves burning a single batch of waste, often

only once per day. Waste is often loaded manually, combusted, and cooled, after which the ash is

manually removed. Intermittent duty incinerators are loaded continuously and frequently with small

waste batches and operate less than 24 h per day. A typical operating cycle for an intermittent duty

system includes a 15- to 30-min period of cleanout of ash from the previous day, a 15- to 60-min

preheat, a 12- to 14-h waste combustion period, a 2- to 4-h burndown period, and a 5- to 8-h

cooldown period. Continuous duty incinerators operate 24 h per day and use automatic charging

units, such as a ram-feed system (Figure 20.7), to input waste into the firebox in small, frequent

batches. A mechanism will automatically remove the ash from the incinerator (U.S. EPA, 1991).