Page 623 - Materials Chemistry, Second Edition

P. 623

CAT3525_C20.qxd 1/27/2005 12:54 PM Page 594

594 Waste Management Practices: Municipal, Hazardous, and Industrial

20.6.2 THE MULTIPLE-CHAMBER INCINERATOR

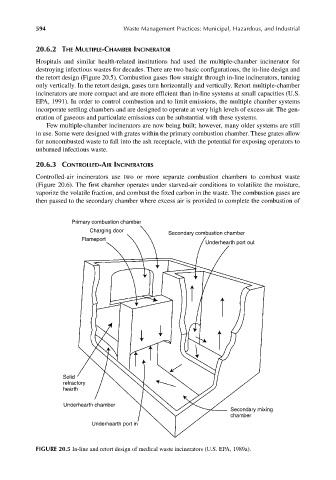

Hospitals and similar health-related institutions had used the multiple-chamber incinerator for

destroying infectious wastes for decades. There are two basic configurations, the in-line design and

the retort design (Figure 20.5). Combustion gases flow straight through in-line incinerators, turning

only vertically. In the retort design, gases turn horizontally and vertically. Retort multiple-chamber

incinerators are more compact and are more efficient than in-line systems at small capacities (U.S.

EPA, 1991). In order to control combustion and to limit emissions, the multiple chamber systems

incorporate settling chambers and are designed to operate at very high levels of excess air. The gen-

eration of gaseous and particulate emissions can be substantial with these systems.

Few multiple-chamber incinerators are now being built; however, many older systems are still

in use. Some were designed with grates within the primary combustion chamber. These grates allow

for noncombusted waste to fall into the ash receptacle, with the potential for exposing operators to

unburned infectious waste.

20.6.3 CONTROLLED-AIR INCINERATORS

Controlled-air incinerators use two or more separate combustion chambers to combust waste

(Figure 20.6). The first chamber operates under starved-air conditions to volatilize the moisture,

vaporize the volatile fraction, and combust the fixed carbon in the waste. The combustion gases are

then passed to the secondary chamber where excess air is provided to complete the combustion of

Primary combustion chamber

Charging door

Secondary combustion chamber

Flameport

Underhearth port out

Solid

refractory

hearth

Underhearth chamber

Secondary mixing

chamber

Underhearth port in

FIGURE 20.5 In-line and retort design of medical waste incinerators (U.S. EPA, 1989a).