Page 628 - Materials Chemistry, Second Edition

P. 628

CAT3525_C20.qxd 1/27/2005 12:54 PM Page 599

Medical and Infectious Wastes 599

used to treat medical waste by both small generators such as healthcare clinics and physicians’offices

and commercial medical waste treatment firms treating waste for a large region.

Sterilization of medical waste involves placing contaminated waste into a sealed chamber and

exposing the waste to pressurized steam of sufficient temperature for a specified length of time to

render them noninfectious. For steam to penetrate the load, the air must be completely removed

from the treatment chamber. Sterilization occurs primarily from the penetration of steam into the

matrix. Heat conduction provides a secondary source of heat transfer.

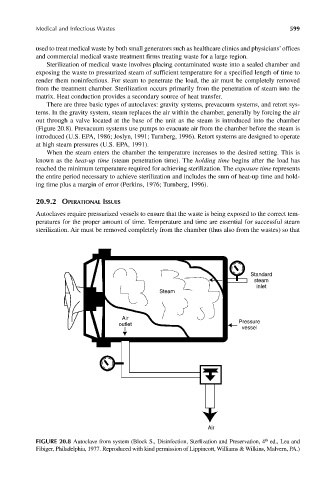

There are three basic types of autoclaves: gravity systems, prevacuum systems, and retort sys-

tems. In the gravity system, steam replaces the air within the chamber, generally by forcing the air

out through a valve located at the base of the unit as the steam is introduced into the chamber

(Figure 20.8). Prevacuum systems use pumps to evacuate air from the chamber before the steam is

introduced (U.S. EPA, 1986; Joslyn, 1991; Turnberg, 1996). Retort systems are designed to operate

at high steam pressures (U.S. EPA, 1991).

When the steam enters the chamber the temperature increases to the desired setting. This is

known as the heat-up time (steam penetration time). The holding time begins after the load has

reached the minimum temperature required for achieving sterilization. The exposure time represents

the entire period necessary to achieve sterilization and includes the sum of heat-up time and hold-

ing time plus a margin of error (Perkins, 1976; Turnberg, 1996).

20.9.2 OPERATIONAL ISSUES

Autoclaves require pressurized vessels to ensure that the waste is being exposed to the correct tem-

peratures for the proper amount of time. Temperature and time are essential for successful steam

sterilization. Air must be removed completely from the chamber (thus also from the wastes) so that

Standard

steam

inlet

Steam

Air

outlet Pressure

vessel

Air

th

FIGURE 20.8 Autoclave from system (Block S., Disinfection, Sterlization and Preservation, 4 ed., Lea and

Fibiger, Philadelphia, 1977. Reproduced with kind permission of Lippincott, Williams & Wilkins, Malvern, PA.)