Page 261 - Fluid Power Engineering

P. 261

228 Chapter Eleven

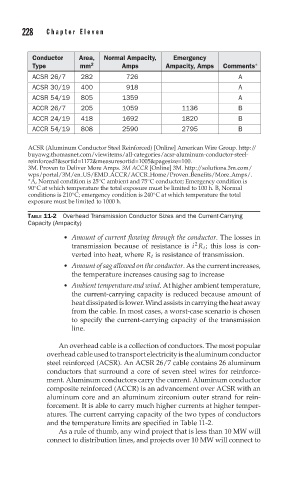

Conductor Area, Normal Ampacity, Emergency

Type mm 2 Amps Ampacity, Amps Comments ∗

ACSR 26/7 282 726 A

ACSR 30/19 400 918 A

ACSR 54/19 805 1359 A

ACCR 26/7 205 1059 1136 B

ACCR 24/19 418 1692 1820 B

ACCR 54/19 808 2590 2795 B

ACSR (Aluminum Conductor Steel Reinforced) [Online] American Wire Group. http://

buyawg.thomasnet.com/viewitems/all-categories/acsr-aluminum-conductor-steel-

reinforced?&sortid=1172&measuresortid=1005&pagesize=100.

3M. Proven to Deliver More Amps. 3M ACCR [Online] 3M. http://solutions.3m.com/

wps/portal/3M/en US/EMD ACCR/ACCR Home/Proven Benefits/More Amps/.

◦

◦

∗ A, Normal condition is 25 C ambient and 75 C conductor; Emergency condition is

◦

90 C at which temperature the total exposure must be limited to 100 h. B, Normal

◦

◦

conditions is 210 C; emergency condition is 240 C at which temperature the total

exposure must be limited to 1000 h.

TABLE 11-2 Overhead Transmission Conductor Sizes and the Current-Carrying

Capacity (Ampacity)

Amount of current flowing through the conductor. The losses in

2

transmission because of resistance is i R t ; this loss is con-

verted into heat, where R t is resistance of transmission.

Amount of sag allowed on the conductor. As the current increases,

the temperature increases causing sag to increase

Ambient temperature and wind. At higher ambient temperature,

the current-carrying capacity is reduced because amount of

heatdissipatedislower.Windassistsincarryingtheheataway

from the cable. In most cases, a worst-case scenario is chosen

to specify the current-carrying capacity of the transmission

line.

An overhead cable is a collection of conductors. The most popular

overheadcableusedtotransportelectricityisthealuminumconductor

steel reinforced (ACSR). An ACSR 26/7 cable contains 26 aluminum

conductors that surround a core of seven steel wires for reinforce-

ment. Aluminum conductors carry the current. Aluminum conductor

composite reinforced (ACCR) is an advancement over ACSR with an

aluminum core and an aluminum zirconium outer strand for rein-

forcement. It is able to carry much higher currents at higher temper-

atures. The current carrying capacity of the two types of conductors

and the temperature limits are specified in Table 11-2.

As a rule of thumb, any wind project that is less than 10 MW will

connect to distribution lines, and projects over 10 MW will connect to