Page 131 - Wire Bonding in Microelectronics

P. 131

W ir e Bond Testing 109

4.3.8 Comparison of the Ball-Shear and the Bond-Pull Tests

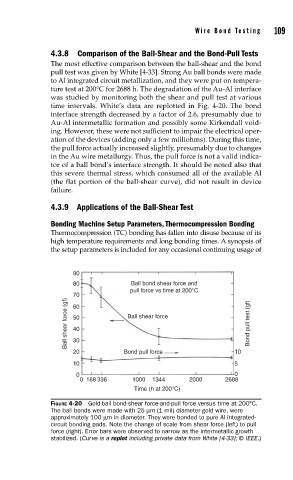

The most effective comparison between the ball-shear and the bond

pull test was given by White [4-33]. Strong Au ball bonds were made

to Al integrated circuit metallization, and they were put on tempera-

ture test at 200°C for 2688 h. The degradation of the Au-Al interface

was studied by monitoring both the shear and pull test at various

time intervals. White’s data are replotted in Fig. 4-20. The bond

interface strength decreased by a factor of 2.6, presumably due to

Au-Al intermetallic formation and possibly some Kirkendall void-

ing. However, these were not sufficient to impair the electrical oper-

ation of the devices (adding only a few milliohms). During this time,

the pull force actually increased slightly, presumably due to changes

in the Au wire metallurgy. Thus, the pull force is not a valid indica-

tor of a ball bond’s interface strength. It should be noted also that

this severe thermal stress, which consumed all of the available Al

(the flat portion of the ball-shear curve), did not result in device

failure.

4.3.9 Applications of the Ball-Shear Test

Bonding Machine Setup Parameters, Thermocompression Bonding

Thermocompression (TC) bonding has fallen into disuse because of its

high temperature requirements and long bonding times. A synopsis of

the setup parameters is included for any occasional continuing usage of

90

80 Ball bond shear force and

pull force vs time at 200°C

70

Ball shear force (gf) 50 Ball shear force Bond pull test (gf)

60

40

30

20 Bond pull force 10

10 5

0 0

0 168 336 1000 1344 2000 2688

Time (h at 200°C)

FIGURE 4-20 Gold-ball bond-shear force-and-pull force versus time at 200°C.

The ball bonds were made with 25 µm (1 mil) diameter gold wire, were

approximately 100 µm in diameter. They were bonded to pure Al integrated-

circuit bonding pads. Note the change of scale from shear force (left) to pull

force (right). Error bars were observed to narrow as the intermetallic growth

stabilized. (Curve is a replot including private data from White [4-33]; © IEEE.)