Page 135 - Wire Bonding in Microelectronics

P. 135

W ir e Bond Testing 113

28 Bond shear force and pull force

vs. bond deformation for aluminum

wedge bonds

24

20

Force (gf) 16

12

8

Bond pull test

4 Shear test, unpulled bonds

Shear test on wedge after pulling

0

Low Medium High

deformation deformation deformation

1.4 1.8 2.8

Deformation (wire diameters)

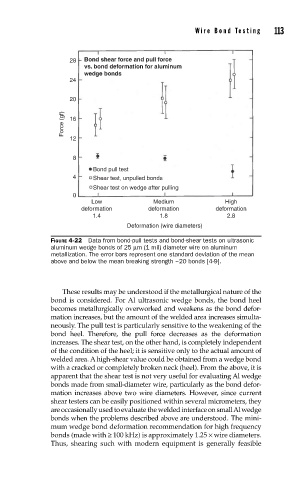

FIGURE 4-22 Data from bond-pull tests and bond-shear tests on ultrasonic

aluminum wedge bonds of 25 µm (1 mil) diameter wire on aluminum

metallization. The error bars represent one standard deviation of the mean

above and below the mean breaking strength ~20 bonds [4-9].

These results may be understood if the metallurgical nature of the

bond is considered. For Al ultrasonic wedge bonds, the bond heel

becomes metallurgically overworked and weakens as the bond defor-

mation increases, but the amount of the welded area increases simulta-

neously. The pull test is particularly sensitive to the weakening of the

bond heel. Therefore, the pull force decreases as the deformation

increases. The shear test, on the other hand, is completely independent

of the condition of the heel; it is sensitive only to the actual amount of

welded area. A high-shear value could be obtained from a wedge bond

with a cracked or completely broken neck (heel). From the above, it is

apparent that the shear test is not very useful for evaluating Al wedge

bonds made from small-diameter wire, particularly as the bond defor-

mation increases above two wire diameters. However, since current

shear testers can be easily positioned within several micrometers, they

are occasionally used to evaluate the welded interface on small Al wedge

bonds when the problems described above are understood. The mini-

mum wedge bond deformation recommendation for high frequency

bonds (made with ≥ 100 kHz) is approximately 1.25 × wire diameters.

Thus, shearing such with modern equipment is generally feasible