Page 137 - Wire Bonding in Microelectronics

P. 137

W ir e Bond Testing 115

Shear testing has been used for years to test the integrity of TAB

bumps at the wafer level. It was also used to measure the strength of

the bonding between the TAB lead and the bump as well as the lead

buckling force [4-46]. Typically, such tests were performed with a wire-

bond ball-shear tester. The shear test is universally used to determine

the strength of solder balls on chips for flip-chip attachment.

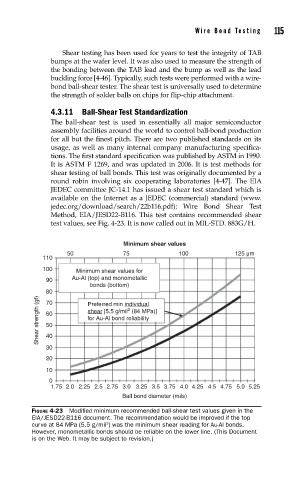

4.3.11 Ball-Shear Test Standardization

The ball-shear test is used in essentially all major semiconductor

assembly facilities around the world to control ball-bond production

for all but the finest pitch. There are two published standards on its

usage, as well as many internal company manufacturing specifica-

tions. The first standard specification was published by ASTM in 1990.

It is ASTM F 1269, and was updated in 2006. It is test methods for

shear testing of ball bonds. This test was originally documented by a

round robin involving six cooperating laboratories [4-47]. The EIA

JEDEC committee JC-14.1 has issued a shear test standard which is

available on the Internet as a JEDEC (commercial) standard (www.

jedec.org/download/search/22b116.pdf): Wire Bond Shear Test

Method, EIA/JESD22-B116. This test contains recommended shear

test values, see Fig. 4-23. It is now called out in MIL-STD. 883G/H.

Minimum shear values

50 75 100 125 µm

110

100 Minimum shear values for

90 Au-Al (top) and monometallic

bonds (bottom)

80 Preferred min individual

Shear strength (gf) 60 shear [5.5 g/mil (84 MPa)]

70

2

for Au-Al bond reliability

50

40

30

20

10

0

1.75 2.0 2.25 2.5 2.75 3.0 3.25 3.5 3.75 4.0 4.25 4.5 4.75 5.0 5.25

Ball bond diameter (mils)

FIGURE 4-23 Modifi ed minimum recommended ball-shear test values given in the

EIA/JESD22-B116 document. The recommendation would be improved if the top

curve at 84 MPa (5.5 g/mil ) was the minimum shear reading for Au-Al bonds.

2

However, monometallic bonds should be reliable on the lower line. (This Document

is on the Web. It may be subject to revision.)