Page 132 - Wire Bonding in Microelectronics

P. 132

110 Cha pte r F o u r

this technology. It was used for much early work that is still part of the

basis of our understanding of bonding and was essential in developing

the ball-shear test. Directly or indirectly, the majority of published work

on the ball-shear test has resulted in improving the setup parameters of

bonding machines. Generally, for TC bonding, the machine is set up for

a bond interface temperature of 300°C, a bonding time of 0.2 s, and a

bonding force of 100 to 125 gf to obtain strong thermocompression ball

bonds from 25 µm (1 mil) diameter gold-wire on either Al or Au metal-

lizations. These parameters offer good shear strength, even in the pres-

ence of a moderate amount of organic contamination [4-14, 4-16]. Typi-

cally, the higher the temperature the greater the bond strength if some

contamination is present, see Chap. 7.

Bonding Machine Setup Parameters, Thermosonic Bonding

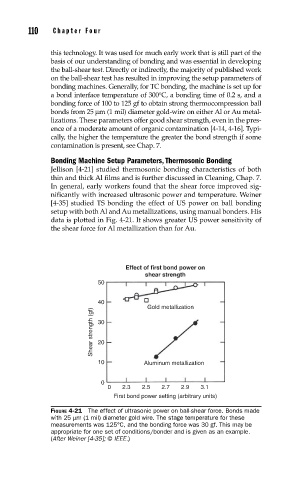

Jellison [4-21] studied thermosonic bonding characteristics of both

thin and thick Al films and is further discussed in Cleaning, Chap. 7.

In general, early workers found that the shear force improved sig-

nificantly with increased ultrasonic power and temperature. Weiner

[4-35] studied TS bonding the effect of US power on ball bonding

setup with both Al and Au metallizations, using manual bonders. His

data is plotted in Fig. 4-21. It shows greater US power sensitivity of

the shear force for Al metallization than for Au.

Effect of first bond power on

shear strength

50

40

Gold metallization

Shear strength (gf) 30

20

10 Aluminum metallization

0

0 2.3 2.5 2.7 2.9 3.1

First bond power setting (arbitrary units)

FIGURE 4-21 The effect of ultrasonic power on ball-shear force. Bonds made

with 25 µm (1 mil) diameter gold wire. The stage temperature for these

measurements was 125°C, and the bonding force was 30 gf. This may be

appropriate for one set of conditions/bonder and is given as an example.

(After Weiner [4-35]; © IEEE.)