Page 398 - Mechanical Behavior of Materials

P. 398

Section 8.10 Summary 399

crack and member geometry; the loading configuration, such as tension or bending; and the ratio of

the crack length to the width of the member, such as the ratio a/b. Some notable values of F for

relatively short cracks under tension stress are as follows:

F = 1.00 (center-cracked plate)

F = 1.12 (through-thickness or circumferential surface crack)

(8.51)

F = 0.73 (half-circular surface crack)

F = 0.72 (quarter-circular corner crack)

It is sometimes convenient to express K in terms of an applied force P by using the differently

defined dimensionless quantity F P according to Eq. 8.13.

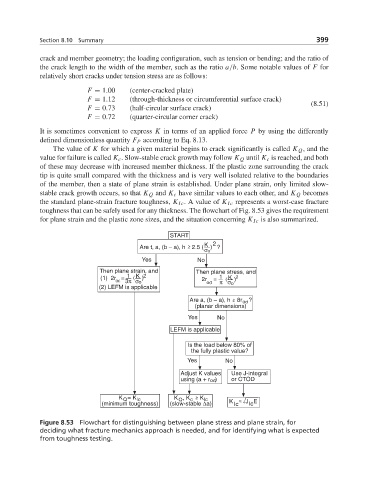

The value of K for which a given material begins to crack significantly is called K Q , and the

value for failure is called K c . Slow-stable crack growth may follow K Q until K c is reached, and both

of these may decrease with increased member thickness. If the plastic zone surrounding the crack

tip is quite small compared with the thickness and is very well isolated relative to the boundaries

of the member, then a state of plane strain is established. Under plane strain, only limited slow-

stable crack growth occurs, so that K Q and K c have similar values to each other, and K Q becomes

the standard plane-strain fracture toughness, K Ic . A value of K Ic represents a worst-case fracture

toughness that can be safely used for any thickness. The flowchart of Fig. 8.53 gives the requirement

for plane strain and the plastic zone sizes, and the situation concerning K Ic is also summarized.

START

K 2

Are t, a, (b – a), h 2.5 ( ) ?

σο

Yes No

Then plane strain, and Then plane stress, and

(

(

(1) 2r = 1 K 2 2r = 1 K 2

)

)

oε 3π σo oσ π σ o

(2) LEFM is applicable

Are a, (b – a), h 8r ?

oσ

(planar dimensions)

Yes No

LEFM is applicable

Is the load below 80% of

the fully plastic value?

Yes No

Adjust K values Use J-integral

using (a + r ) or CTOD

oσ

K = K Ic K , K K Ic

Q

Q

c

Ic

(minimum toughness) (slow-stable Δa) K Ic J E

Figure 8.53 Flowchart for distinguishing between plane stress and plane strain, for

deciding what fracture mechanics approach is needed, and for identifying what is expected

from toughness testing.