Page 166 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 166

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap12 Final Proof page 162 4.1.2007 2:43pm Compositor Name: SJoearun

12/162 ARTIFICIAL LIFT METHODS

12.1 Introduction by means of the walking beam through a pitman arm. The

horse’s head and the hanger cable arrangement is used to

Sucker rod pumping is also referred to as ‘‘beam pump-

ing.’’ It provides mechanical energy to lift oil from bottom ensure that the upward pull on the sucker rod string is

hole to surface. It is efficient, simple, and easy for field vertical at all times (thus, no bending moment is applied to

people to operate. It can pump a well down to very low the stuffing box). The polished rod and stuffing box com-

pressure to maximize oil production rate. It is applicable to bine to maintain a good liquid seal at the surface and, thus,

slim holes, multiple completions, and high-temperature force fluid to flow into the ‘‘T’’ connection just below the

and viscous oils. The system is also easy to change to stuffing box.

other wells with minimum cost. The major disadvantages Conventional pumping units are available in a wide

of beam pumping include excessive friction in crooked/ range of sizes, with stroke lengths varying from 12 to

deviated holes, solid-sensitive problems, low efficiency in almost 200 in. The strokes for any pumping unit type are

gassy wells, limited depth due to rod capacity, and bulky in available in increments (unit size). Within each unit size,

offshore operations. Beam pumping trends include the stroke length can be varied within limits (about six

improved pump-off controllers, better gas separation, gas different lengths being possible). These different lengths

handling pumps, and optimization using surface and are achieved by varying the position of the pitman arm

bottom-hole cards. connection on the crank arm.

Walking beam ratings are expressed in allowable pol-

ished rod loads (PRLs) and vary from approximately

3,000 to 35,000 lb. Counterbalance for conventional

12.2 Pumping System

pumping units is accomplished by placing weights directly

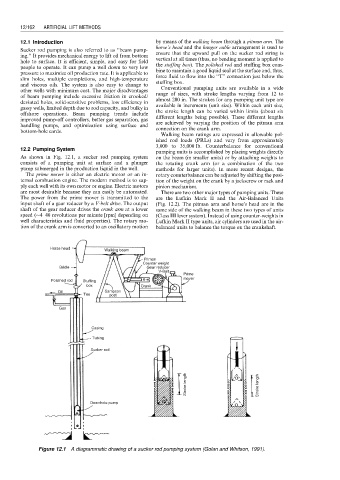

As shown in Fig. 12.1, a sucker rod pumping system on the beam (in smaller units) or by attaching weights to

consists of a pumping unit at surface and a plunger the rotating crank arm (or a combination of the two

pump submerged in the production liquid in the well. methods for larger units). In more recent designs, the

The prime mover is either an electric motor or an in- rotary counterbalance can be adjusted by shifting the posi-

ternal combustion engine. The modern method is to sup- tion of the weight on the crank by a jackscrew or rack and

ply each well with its own motor or engine. Electric motors pinion mechanism.

are most desirable because they can easily be automated. There are two other major types of pumping units. These

The power from the prime mover is transmitted to the are the Lufkin Mark II and the Air-Balanced Units

input shaft of a gear reducer by a V-belt drive. The output (Fig. 12.2). The pitman arm and horse’s head are in the

shaft of the gear reducer drives the crank arm at a lower same side of the walking beam in these two types of units

speed ( 4–40 revolutions per minute [rpm] depending on (Class III lever system). Instead of using counter-weights in

well characteristics and fluid properties). The rotary mo- Lufkin Mark II type units, air cylinders are used in the air-

tion of the crank arm is converted to an oscillatory motion balanced units to balance the torque on the crankshaft.

Horse head

Walking beam

Pitman

Counter weight

Bridle Gear reducer

V-Belt

Prime

mover

Polished rod Stuffing

box Crank

Oil Sampson

Tee post

Gas

Casing

Tubing

Sucker rod

Stroke length Stroke length

Downhole pump

Figure 12.1 A diagrammatic drawing of a sucker rod pumping system (Golan and Whitson, 1991).