Page 187 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 187

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 183 3.1.2007 9:07pm Compositor Name: SJoearun

GAS LIFT 13/183

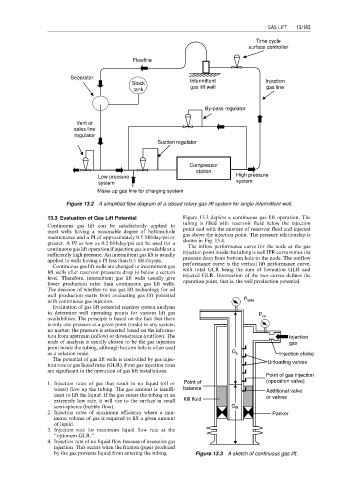

Time cycle

surface controller

Flowline

Separator

Stock Intermittent Injection

tank gas lift well gas line

By-pass regulator

Vent or

sales line

regulator

Suction regulator

Compressor

station

Low pressure High pressure

system system

Make-up gas line for charging system

Figure 13.2 A simplified flow diagram of a closed rotary gas lift system for single intermittent well.

13.3 Evaluation of Gas Lift Potential Figure 13.3 depicts a continuous gas lift operation. The

tubing is filled with reservoir fluid below the injection

Continuous gas lift can be satisfactorily applied to

most wells having a reasonable degree of bottom-hole point and with the mixture of reservoir fluid and injected

maintenance and a PI of approximately 0.5 bbl/day/psi or gas above the injection point. The pressure relationship is

greater. A PI as low as 0.2 bbl/day/psi can be used for a shown in Fig. 13.4.

continuous gas lift operation if injection gas is available at a The inflow performance curve for the node at the gas

sufficiently high pressure. An intermittent gas lift is usually injection point inside the tubing is well IPR curve minus the

applied to wells having a PI less than 0.5 bbl/day/psi. pressure drop from bottom hole to the node. The outflow

Continuous gas lift wells are changed to intermittent gas performance curve is the vertical lift performance curve,

with total GLR being the sum of formation GLR and

lift wells after reservoir pressures drop to below a certain injected GLR. Intersection of the two curves defines the

level. Therefore, intermittent gas lift wells usually give

operation point, that is, the well production potential.

lower production rates than continuous gas lift wells.

The decision of whether to use gas lift technology for oil

well production starts from evaluating gas lift potential

with continuous gas injection. P WH

Evaluation of gas lift potential requires system analyses

to determine well operating points for various lift gas P

availabilities. The principle is based on the fact that there cs

is only one pressure at a given point (node) in any system;

no matter, the pressure is estimated based on the informa-

tion from upstream (inflow) or downstream (outflow). The Injection

node of analysis is usually chosen to be the gas injection gas

point inside the tubing, although bottom hole is often used

as a solution node. G u Injection choke

The potential of gas lift wells is controlled by gas injec- Unloading valves

tion rate or gas liquid ratio (GLR). Four gas injection rates

are significant in the operation of gas lift installations:

Point of gas injection

1. Injection rates of gas that result in no liquid (oil or Point of (operation valve)

water) flow up the tubing. The gas amount is insuffi- balance Additional valve

cient to lift the liquid. If the gas enters the tubing at an or valves

extremely low rate, it will rise to the surface in small Kill fluid

semi-spheres (bubbly flow). G R

2. Injection rates of maximum efficiency where a min- Packer

imum volume of gas is required to lift a given amount

of liquid.

3. Injection rate for maximum liquid flow rate at the

‘‘optimum GLR.’’

4. Injection rate of no liquid flow because of excessive gas

injection. This occurs when the friction (pipe) produced

by the gas prevents liquid from entering the tubing. Figure 13.3 A sketch of continuous gas lift.