Page 233 -

P. 233

SLOW SAND AND DIATOMACEOUS EARTH FILTRATION 9.9

TO DISTRIBUTION

SYSTEM

I

.RCM

CONTROL

RESERVOIR

BUILDING

, ~RED

t WAI~R

PIFING GALLERY

FILTER F[ LTER FILTER FILTER

NO. 1 NO. 2 NO. ,3 NO. 4

ENTRANCE ENTRANCE

STRUCTURE STRUCTURE

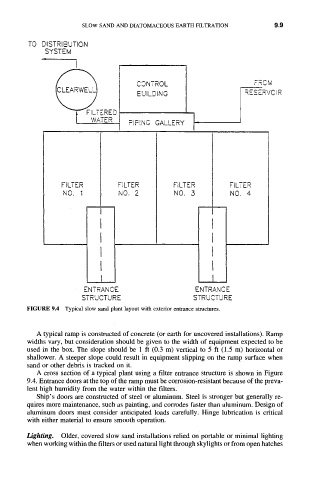

FIGURE 9.4 Typical slow sand plant layout with exterior entrance structures.

A typical ramp is constructed of concrete (or earth for uncovered installations). Ramp

widths vary, but consideration should be given to the width of equipment expected to be

used in the box. The slope should be 1 ft (0.3 m) vertical to 5 ft (1.5 m) horizontal or

shallower. A steeper slope could result in equipment slipping on the ramp surface when

sand or other debris is tracked on it.

A cross section of a typical plant using a filter entrance structure is shown in Figure

9.4. Entrance doors at the top of the ramp must be corrosion-resistant because of the preva-

lent high humidity from the water within the filters.

Ship's doors are constructed of steel or aluminum. Steel is stronger but generally re-

quires more maintenance, such as painting, and corrodes faster than aluminum. Design of

aluminum doors must consider anticipated loads carefully. Hinge lubrication is critical

with either material to ensure smooth operation.

Lighting. Older, covered slow sand installations relied on portable or minimal lighting

when working within the filters or used natural light through skylights or from open hatches