Page 117 - 15 Dangerously Mad Projects for the Evil Genius

P. 117

96 15 Dangerously Mad Projects for the Evil Genius

Apart from attaching the assembly to a motor,

which we will deal with in the next section, that’s

about it for the LED assembly.

Motor Controller

We need to be able to control the speed of the

motor, because it must match the speed at which

the LEDs switch from displaying one column to

the next. There is no sensor to automatically

synchronize the LEDs with the spinning motor. It’s

actually more fun without this, as the letters can be

Figure 8-23 The battery clip for the LED unit

made to process around the display by tweaking

the motor’s speed.

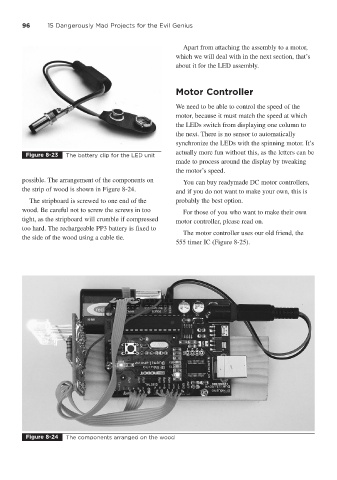

possible. The arrangement of the components on You can buy readymade DC motor controllers,

the strip of wood is shown in Figure 8-24. and if you do not want to make your own, this is

The stripboard is screwed to one end of the probably the best option.

wood. Be careful not to screw the screws in too For those of you who want to make their own

tight, as the stripboard will crumble if compressed motor controller, please read on.

too hard. The rechargeable PP3 battery is fixed to

The motor controller uses our old friend, the

the side of the wood using a cable tie.

555 timer IC (Figure 8-25).

Figure 8-24 The components arranged on the wood