Page 135 - 3D Fibre Reinforced Polymer Composites

P. 135

124 30 Fibre Reinforced Polymer Composites

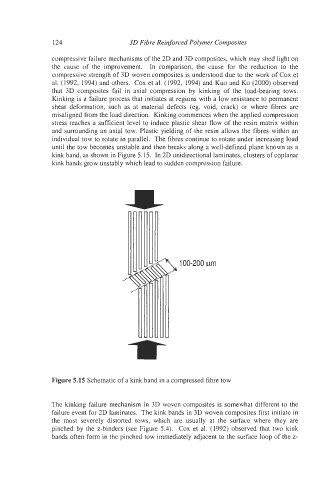

compressive failure mechanisms of the 2D and 3D composites, which may shed light on

the cause of the improvement. In comparison, the cause for the reduction to the

compressive strength of 3D woven composites is understood due to the work of Cox et

al. (1992, 1994) and others. Cox et al. (1992, 1994) and Kuo and KO (2000) observed

that 3D composites fail in axial compression by kinking of the load-bearing tows.

Kinking is a failure process that initiates at regions with a low resistance to permanent

shear deformation, such as at material defects (eg. void, crack) or where fibres are

misaligned from the load direction. Kinking commences when the applied compression

stress reaches a sufficient level to induce plastic shear flow of the resin matrix within

and surrounding an axial tow. Plastic yielding of the resin allows the fibres within an

individual tow to rotate in parallel. The fibres continue to rotate under increasing load

until the tow becomes unstable and then breaks along a well-defined plane known as a

kink band, as shown in Figure 5.15. In 2D unidirectional laminates, clusters of coplanar

kink bands grow unstably which lead to sudden compression failure.

Figure 5.15 Schematic of a kink band in a compressed fibre tow

The kinking failure mechanism in 3D woven composites is somewhat different to the

failure event for 2D laminates. The kink bands in 3D woven composites first initiate in

the most severely distorted tows, which are usually at the surface where they are

pinched by the z-binders (see Figure 5.4). Cox et al. (1992) observed that two kink

bands often form in the pinched tow immediately adjacent to the surface loop of the z-