Page 136 - 3D Fibre Reinforced Polymer Composites

P. 136

30 Woven Composites 125

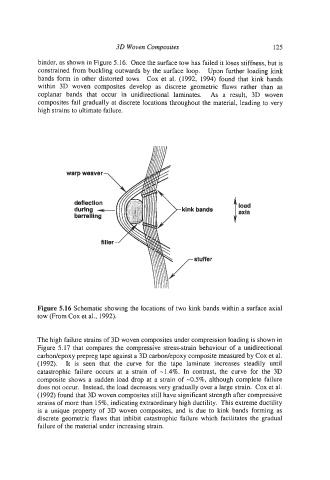

binder, as shown in Figure 5.16. Once the surface tow has failed it loses stiffness, but is

constrained from buckling outwards by the surface loop. Upon further loading kink

bands form in other distorted tows. Cox et al. (1992, 1994) found that kink bands

within 3D woven composites develop as discrete geometric flaws rather than as

coplanar bands that occur in unidirectional laminates. As a result, 3D woven

composites fail gradually at discrete locations throughout the material, leading to very

high strains to ultimate failure.

-kink bands

/-stut(er

Figure 5.16 Schematic showing the locations of two kink bands within a surface axial

tow (From Cox et al., 1992).

The high failure strains of 3D woven composites under compression loading is shown in

Figure 5.17 that compares the compressive stress-strain behaviour of a unidirectional

carbodepoxy prepreg tape against a 3D carbodepoxy composite measured by Cox et al.

(1992). It is seen that the curve for the tape laminate increases steadily until

catastrophic failure occurs at a strain of -1.4%. In contrast, the curve for the 3D

composite shows a sudden load drop at a strain of -OS%, although complete failure

does not occur. Instead, the load decreases very gradually over a large strain. Cox et al.

( 1992) found that 3D woven composites still have significant strength after compressive

strains of more than 15%, indicating extraordinary high ductility. This extreme ductility

is a unique property of 3D woven composites, and is due to kink bands forming as

discrete geometric flaws that inhibit catastrophic failure which facilitates the gradual

failure of the material under increasing strain.