Page 201 - A Comprehensive Guide to Solar Energy Systems

P. 201

Chapter 9 • Crystalline Silicon Solar Cell and Module Technology 203

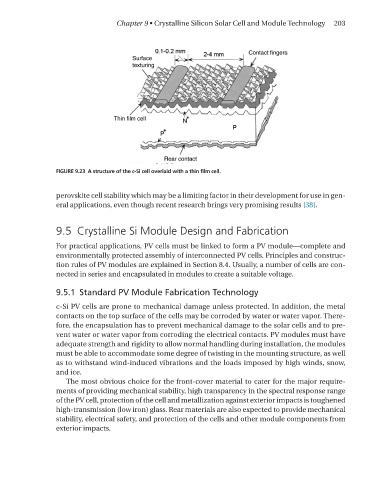

FIGURE 9.23 A structure of the c-Si cell overlaid with a thin film cell.

perovskite cell stability which may be a limiting factor in their development for use in gen-

eral applications, even though recent research brings very promising results [38].

9.5 Crystalline Si Module Design and Fabrication

For practical applications, PV cells must be linked to form a PV module—complete and

environmentally protected assembly of interconnected PV cells. Principles and construc-

tion rules of PV modules are explained in Section 8.4. Usually, a number of cells are con-

nected in series and encapsulated in modules to create a suitable voltage.

9.5.1 Standard PV Module Fabrication Technology

c-Si PV cells are prone to mechanical damage unless protected. In addition, the metal

contacts on the top surface of the cells may be corroded by water or water vapor. There-

fore, the encapsulation has to prevent mechanical damage to the solar cells and to pre-

vent water or water vapor from corroding the electrical contacts. PV modules must have

adequate strength and rigidity to allow normal handling during installation, the modules

must be able to accommodate some degree of twisting in the mounting structure, as well

as to withstand wind-induced vibrations and the loads imposed by high winds, snow,

and ice.

The most obvious choice for the front-cover material to cater for the major require-

ments of providing mechanical stability, high transparency in the spectral response range

of the PV cell, protection of the cell and metallization against exterior impacts is toughened

high-transmission (low iron) glass. rear materials are also expected to provide mechanical

stability, electrical safety, and protection of the cells and other module components from

exterior impacts.