Page 338 - Adsorbents fundamentals and applications

P. 338

METHANE STORAGE 323

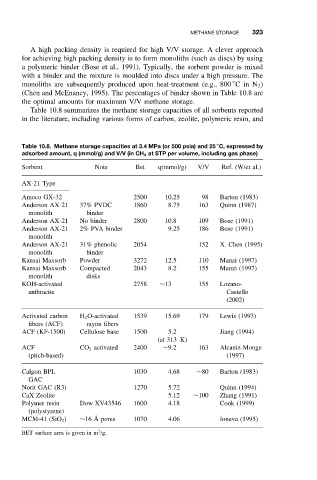

A high packing density is required for high V/V storage. A clever approach

for achieving high packing density is to form monoliths (such as discs) by using

a polymeric binder (Bose et al., 1991). Typically, the sorbent powder is mixed

with a binder and the mixture is moulded into discs under a high pressure. The

◦

monoliths are subsequently produced upon heat-treatment (e.g., 800 CinN 2 )

(Chen and McEnaney, 1995). The percentages of binder shown in Table 10.8 are

the optimal amounts for maximum V/V methane storage.

Table 10.8 summarizes the methane storage capacities of all sorbents reported

in the literature, including various forms of carbon, zeolite, polymeric resin, and

◦

Table 10.8. Methane storage capacities at 3.4 MPa (or 500 psia) and 25 C, expressed by

adsorbed amount, q (mmol/g) and V/V (in CH 4 at STP per volume, including gas phase)

Sorbent Note Bet q(mmol/g) V/V Ref. (W/et al.)

AX-21 Type

Amoco GX-32 2500 10.25 98 Barton (1983)

Anderson AX-21 37% PVDC 1860 8.75 163 Quinn (1987)

monolith binder

Anderson AX-21 No binder 2800 10.8 109 Bose (1991)

Anderson AX-21 2% PVA binder 9.25 186 Bose (1991)

monolith

Anderson AX-21 31% phenolic 2054 152 X. Chen (1995)

monolith binder

Kansai Maxsorb Powder 3272 12.5 110 Manzi (1997)

Kansai Maxsorb Compacted 2043 8.2 155 Manzi (1997)

monolith disks

KOH-activated 2758 ∼13 155 Lozano-

anthracite Castello

(2002)

Activated carbon H 2 O-activated 1539 15.69 179 Lewis (1993)

fibers (ACF) rayon fibers

ACF (KF-1500) Cellulose base 1500 5.2 Jiang (1994)

(at 313 K)

ACF CO 2 activated 2400 ∼9.2 163 Alcaniz-Monge

(pitch-based) (1997)

Calgon BPL 1030 4.68 ∼80 Barton (1983)

GAC

Norit GAC (R3) 1270 5.72 Quinn (1994)

CaX Zeolite 5.12 ∼100 Zhang (1991)

Polymer resin Dow XV43546 1600 4.18 Cook (1999)

(polystyrene)

MCM-41 (SiO 2 ) ∼16 ˚ A pores 1070 4.06 Ioneva (1995)

2

BET surface area is given in m /g.