Page 17 - Adsorption Technology & Design, Elsevier (1998)

P. 17

14 Adsorbents

02

1.0

Fraction

of maximum

(equilibrium)

loading N2

30 60 90

Time minutes.

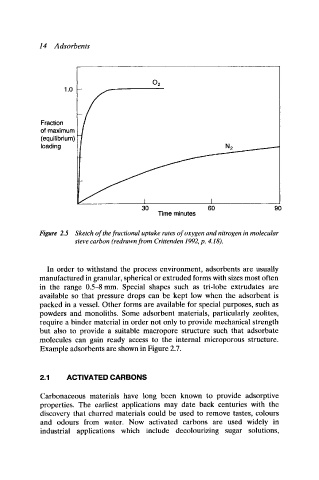

Figure 2.5 Sketch of the fractional uptake rates of oxygen and nitrogen in molecular

sieve carbon (redrawn from Crittenden 1992, p. 4.18).

In order to withstand the process environment, adsorbents are usually

manufactured in granular, spherical or extruded forms with sizes most often

in the range 0.5-8 mm. Special shapes such as tri-lobe extrudates are

available so that pressure drops can be kept low when the adsorbent is

packed in a vessel. Other forms are available for special purposes, such as

powders and monoliths. Some adsorbent materials, particularly zeolites,

require a binder material in order not only to provide mechanical strength

but also to provide a suitable macropore structure such that adsorbate

molecules can gain ready access to the internal microporous structure.

Example adsorbents are shown in Figure 2.7.

2.1 ACTIVATED CARBONS

Carbonaceous materials have long been known to provide adsorptive

properties. The earliest applications may date back centuries with the

discovery that charred materials could be used to remove tastes, colours

and odours from water. Now activated carbons are used widely in

industrial applications which include decolourizing sugar solutions,